THE COMPLETE GUIDE TO WELDING

FUME EXTRACTION SYSTEMS:

HOW (AND WHY) TO KEEP YOUR FACILITY AIR CLEAN AND SAFE

CHAPTER ONE: WELD FUME BASICS

Weld fumes create hazards for welders and others who are exposed to fumes that can propagate throughout the space. Understanding the composition of weld fumes and their health and safety risks is the first step to designing a weld fume removal strategy.

What is weld fume composed of?

Weld fumes are a complex mix of oxidized and unoxidized metals, silicates, fluorides, welding gases and other materials, including solid particulate, vapors and gases. Most of the solid particles that make up weld fumes are in the sub-micron range, which creates challenges for weld fume collection and filtration. For MIG (GMAW), stick (TMAW) and flux-cored welding, the majority of weld fume comes from the welding consumable (the welding wire or rod). But even laser welding and resistance welding can produce significant fume from base metals and coatings, especially if metals are galvanized, painted or contaminated with lubricants.

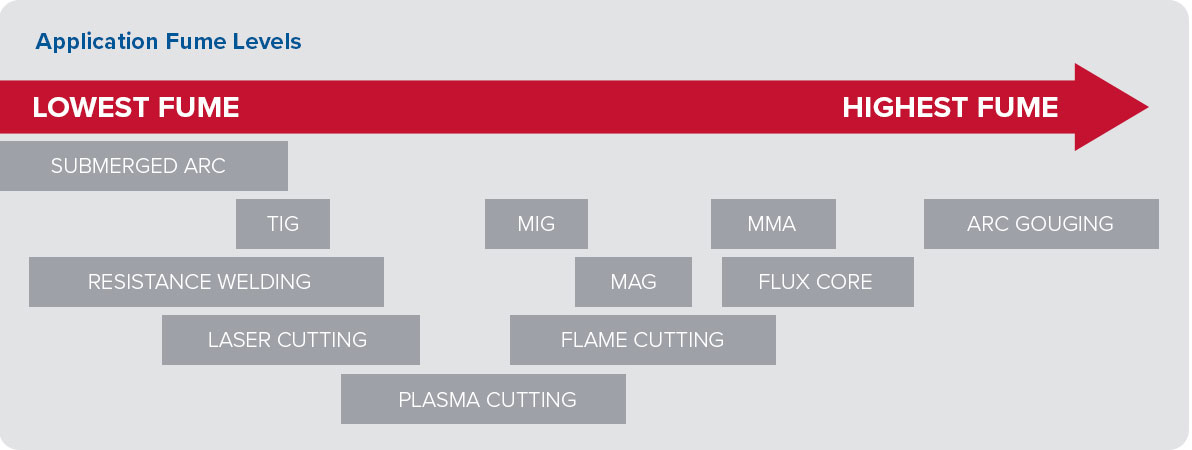

Which welding processes produce the most fumes?

In general, welding processes that use consumables–such as MIG (GMAW), TIG (GTAW), arc welding, stick welding, and flux-cored welding–produce more fumes than resistance welding or laser welding. Most of the weld fume comes from the welding consumable. However, that does not mean that resistance and laser welding do not produce fumes. These types of welding can produce dangerous emissions, especially when welding coated or galvanized metals. Learn more about the health risks of different types of welding:

What are the health risks of weld fumes?

Weld fumes are associated with many different kinds of health risks when inhaled. Because particulates in weld fume are very small, they can be breathed deeply into the lungs, where they can cause lung damage or travel through the bloodstream and cause damage to other organs. Many of the substances found in welding smoke, such as hexavalent chromium for stainless steel, are considered to be carcinogenic.

What is Welder’s Lung?

Welder’s Lung is an occupational disease associated with chronic exposure to iron dust and fumes. The formal name for Welder’s Lung is pneumosiderosis. It results from the deposition of metals in the lung tissue. While not limited to welders, welders are considered especially vulnerable because of the very tiny particulate that results from thermal processes such as welding, which allows contaminants to be deposited deeply into lung tissue where they can accumulate. Welder’s Lung may cause coughing, wheezing, shortness of breath and asthma-like symptoms. Over time, pneumosiderosis may progress to fibrosis of the lungs or chronic obstructive pulmonary disease (COPD). The best way to prevent Welder’s Lung is to avoid exposure to weld fumes.

How long does metal fume fever last?

Metal fume fever (or welding flu) is an acute reaction to exposure to welding emissions that causes flu-like symptoms that can persist for 12-48 hours after exposure. Metal fume fever is a common short-term reaction to exposure to welding fumes containing zinc, aluminum, magnesium or oxides of these metals. Symptoms typically include fever, chills, nausea, headache, fatigue, muscle aches, joint pain and shortness of breath. Some welders may also experience dizziness, coughing and changes in blood pressure. Welders experiencing symptoms of metal fume fever should eliminate exposure to weld fumes immediately and be moved to an area with plenty of fresh, clean air. Treatment for mild metal fume fever consists of bed rest, hydration and treatment of symptoms with over-the-counter remedies such as aspirin. Symptoms will usually go away on their own within 48 hours. If symptoms persist or more serious symptoms develop, such as vomiting or difficulty breathing, see a doctor immediately. If welders are frequently experiencing metal fume fever in the facility, this is a sign that weld fume controls are not adequate.

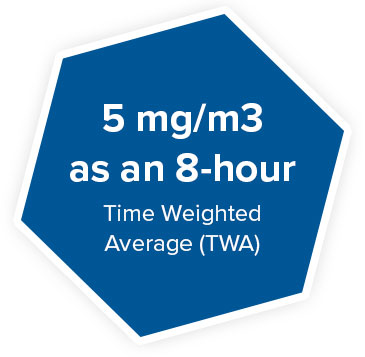

How much welding fume can you breathe in before it becomes harmful?

The OSHA Permissiable Exposure Limit (PEL) for weld fume exposure is no more than 5 mg/m3 as an 8-hour Time Weighted Average (TWA). While it should not be considered “safe” to breathe in any amount of weld fume, exposure risks are strongly correlated to the amount of fume inhaled and the duration of the exposure. Risks are also dependent on the exact composition of the specific fume; risks associated with resistance welding of galvanized steel, for example, will not be the same as the risks associated with MIG welding of stainless steel. The National Institute of Occupational Safety and Health (NIOSH) and the American Congress of Industrial Governmental Hygienists (ACGIH) set exposure guidelines for specific elements found in weld fume (such as zinc oxide, hexavalent chromium, or lead) based on the latest scientific evidence on health risks and outcomes. These recommendations may be lower than the official legal regulatory exposure limit.

How far can welding fumes travel?

Weld fumes can easily propagate throughout the facility if not controlled. Thermal processes like welding create small, lightweight particles and gases that rise from the weld seam and are easily carried by air currents inside the facility. Fugitive weld fumes can easily migrate to locations far from the welding location, though a degree of dilution will occur as they travel through a larger space. The exact migration pattern for fugitive weld fume will depend on the facility layout and airflow patterns. A VentMapping Engineering Study uses Computational Fluid Dynamics to model airflow patterns and fume propagation through a space.

How long can weld fumes persist?

Most of the substances found in welding emissions will not break down on their own; once in the air, they will persist until they are captured and removed or filtered out of the air. That means that absent effective ventilation and/or air filtration, welding fume will continue to build up in an enclosed area, quickly reaching dangerous levels. Ventilation and air filtration can be used to remove weld fume from the space or dilute it to acceptable levels.

How far can welding fumes travel?

Weld fumes can easily propagate throughout the facility if not controlled. Thermal processes like welding create small, lightweight particles and gases that rise from the weld seam and are easily carried by air currents inside the facility. Fugitive weld fumes can easily migrate to locations far from the welding location, though a degree of dilution will occur as they travel through a larger space. The exact migration pattern for fugitive weld fume will depend on the facility layout and airflow patterns. A VentMapping Engineering Study uses Computational Fluid Dynamics to model airflow patterns and fume propagation through a space.

TALK TO AN EXPERT

Want to learn more? Talk to a dust, mist and fume expert today by filling out the fields below.