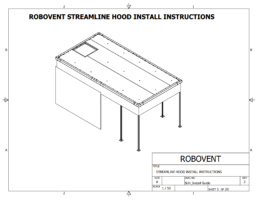

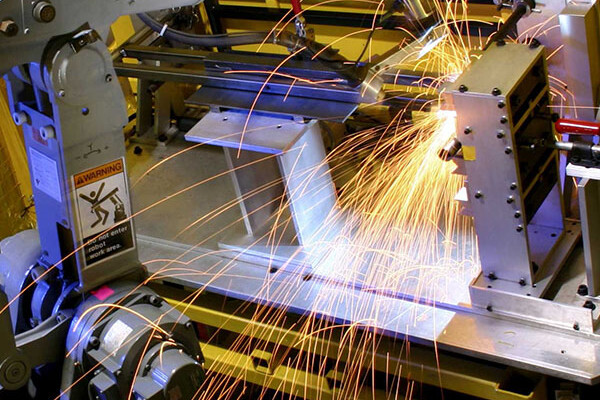

Streamline Hood™: Robotic Welding Hood

A modular industrial hood engineered for efficient source capture in robotic welding and other automated processes.

- Modular, low-profile design saves floor space and installs quickly with standard tools

- Provides effective source capture of welding fumes, dust, mist and sparks

- Custom configurations optimize airflow for energy-efficient fume control

Support Productivity, Compliance and Air Quality with Effective Source Capture

The Streamline Hood is a modular industrial hood system engineered for effective source capture of dust, fumes, mist, and sparks from robotic welding and other automated processes. Its streamlined, low-profile construction saves valuable floor space and installs quickly with standard tools-delivering clean-air performance with minimal disruption to production.

- Maximize floor space: Compact, low-profile design fits closely around robotic cells to free valuable workspace.

- Reduce energy and operating costs: Custom sizing minimizes airflow (CFM) requirements, lowering fan power and energy consumption.

- Accelerate setup and changeovers: Modular construction installs quickly with standard tools for minimal downtime.

- Enhance visibility and safety: Clear panels improve light transfer and oversight within the weld cell.

- Maintain clean, compliant air: Source capture design prevents fume migration and supports OSHA and NFPA standards.

Key Features

Engineered for robotic and automated manufacturing, the Streamline Hood combines efficient fume containment with a lightweight, modular design that installs quickly and performs reliably in demanding production environments.

- Streamlined Design: Low-profile canopy saves valuable floor space while maintaining effective process containment.

- Modular Construction: Built in configurable sections for fast assembly, easy resizing and precise fit to your robotic cell.

- Clear Polygal Top: Provides 95% light transfer for excellent visibility inside the enclosure; no additional lighting required.

- Lightweight Frame: Minimal structural load; no extra reinforcement needed for ceiling or fence-mounted installations.

- Flexible Mounting Options: Secure from the ceiling, cell fencing or the floor to match your layout and access needs.

- Energy-Efficient Source Capture: Reduces airflow (CFM) and energy use by confining fumes directly over the welding process.

- Custom Fabrication: Designed for each cell and application to meet specific ventilation and process requirements.

- Durable Construction: Industrial-grade materials withstand heat, sparks and heavy-duty production environments.

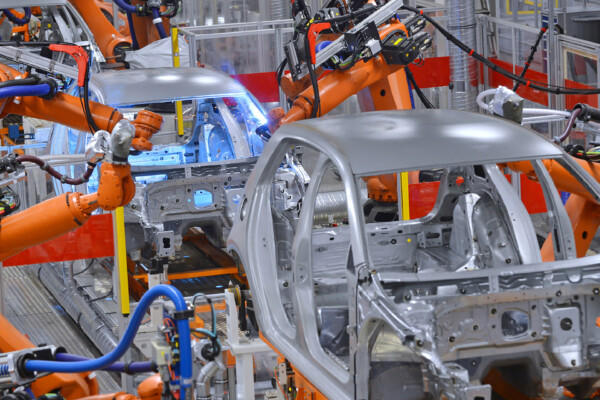

Applications for the Streamline Hood Industrial Enclosure

The Streamline Hood is purpose-built for robotic welding cells and automated industrial environments where consistent fume control and reliable source capture are essential. Its modular, low-profile design integrates seamlessly into high-production manufacturing cells, ensuring cleaner air and safer operations.

- Robotic Welding Cells: Contain fumes, mist and sparks at the source to maintain clean air and clear sightlines.

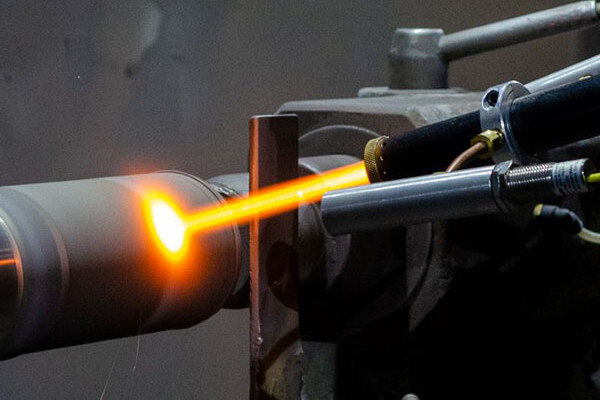

- Resistance Welding and Spot Welding: Capture localized fume emissions from automated joining processes.

- Automated Cutting and Grinding: Control metal dust and particulates generated by automated machining processes.

- Thermal Spray and Plasma Cutting: Isolate high-heat, high-output operations for improved visibility and air quality.

- Metal Fabrication Cells: Support source capture in production lines with multiple robotic or CNC workstations.

Spire™ and Streamline Hood: Better Together

When paired, the Streamline Hood and Spire dust-collector deliver a high-performance solution for robotic welding fume extraction, enabling source capture at the cell and efficient filtration at the collector.

- Space-saving Spire dust collector units are easy to install and accommodate one or two robotic weld cells.

- The Streamline Hood creates a defined capture zone right over the welding process to prevent fume migration and lower airflow needs.

- Together, they minimize ductwork, reduce energy use and simplify maintenance while improving air quality in high-production environments.

- Available in three sizes to accommodate a range of CFM requirements and minimize energy use and operational costs.

FREQUENTLY ASKED QUESTIONS ABOUT STREAMLINE HOOD

Streamline Hood™

How do I know if my fume hood and extraction system is working effectively?

An effective industrial fume hood should consistently capture fumes, dust and mist at the source, keeping them out of the operator’s breathing zone and the surrounding workspace. Signs of poor performance include visible haze or smoke in the air, residue buildup on nearby surfaces, or uneven airflow around the hood opening.

Performance depends on both the hood design and the dust collector’s airflow and filtration efficiency. If airflow has decreased, filters may be clogged, ductwork may be leaking, or the hood may not be properly sized or positioned for the process. Routine inspection, airflow testing and maintenance are essential to ensure safe, compliant and energy-efficient operation.

What materials and components are used in the Streamline Hood?

The Streamline Hood is built from lightweight, industrial-grade materials designed for durability and ease of installation. The structure uses a steel frame with a clear Polygal top panel that transfers up to 95% of light, improving visibility inside the weld cell. Components are precision-fabricated and powder-coated for long service life, and the overall assembly places minimal structural load on ceilings, cell fencing or floors, eliminating the need for additional reinforcement.

Can the Streamline Hood be modified or expanded for new production lines?

Yes. The Streamline Hood uses a modular design that can be resized, expanded or reconfigured to fit new production layouts. As your automation footprint grows, additional panels or sections can be added to enclose new robotic cells or accommodate changes in tooling and part size. This flexibility allows manufacturers to adapt without replacing the entire enclosure, reducing cost and downtime while maintaining efficient source capture and compliance.

Can the Streamline Hood be installed without major facility modifications?

Yes. The Streamline Hood is engineered for fast, straightforward installation with standard tools and minimal disruption to production. Its lightweight modular panels can be mounted to existing cell fencing, the ceiling or the floor—no special equipment or structural reinforcement required. Because it ships in pre-fabricated sections, most installations can be completed quickly and integrated directly with existing dust or fume collection systems, minimizing both downtime and cost.

Why is sizing important in designing an industrial fume hood?

Proper sizing is critical to the performance and efficiency of any industrial fume hood or welding fume extraction system. A hood that’s too small may not fully contain the process, allowing fumes and particulates to escape. One that’s oversized requires more airflow (CFM) than necessary, driving up energy costs and system requirements.

Right-sizing the hood to the specific process, cell size and airflow pattern ensures effective source capture with minimal energy use. Modular hoods like the Streamline Hood can be configured to match the exact dimensions of the robotic cell, reducing airflow demand, simplifying duct routing and improving overall containment efficiency.

What are the benefits of using a modular hood for robotic welding?

A modular industrial hood provides efficient, reliable source capture for robotic welding operations while maintaining flexibility and ease of installation. Unlike permanent structures or open hoods, modular systems are designed to fit the exact size and layout of each weld cell, reducing airflow requirements and improving overall fume extraction efficiency. Key advantages include:

- Right-sized containment: Encloses the robotic cell for effective fume and mist capture while minimizing airflow (CFM) and energy use.

- Fast, easy installation: Ships in modular sections that assemble quickly with standard tools, reducing installation time and downtime.

- Low-profile design: Saves valuable floor space and allows easy integration with surrounding automation.

- Flexible configuration: Can be mounted to the ceiling, cell fencing or floor to suit any facility layout.

- Seamless integration: Connects easily to ductwork or directly to dust and fume collectors for complete dust, fume and mist control.

Together, these features make modular hoods like the Streamline Hood ideal for high-production robotic welding cells that require consistent containment, efficient air quality management and easy scalability.

What kind of enclosure is needed for robotic welding?

Robotic welding requires an industrial hood or enclosure designed to contain fumes and particulates directly around the weld cell. The most effective systems use a modular hood design, such as the Streamline Hood, which encloses the process area to create a defined capture zone for efficient source capture.

Unlike open canopy-style hoods, modular industrial enclosures surround the robotic work area to prevent fume migration and maintain cleaner air throughout the facility. This configuration allows precise airflow control, reduces energy use, and ensures compliance with OSHA and NFPA standards for welding fume extraction.

DROP US A LINE

Contact RoboVent today to start building your custom dust collection system.