Tru-Form Steel & Wire: Better Air Leads to Productivity Improvements

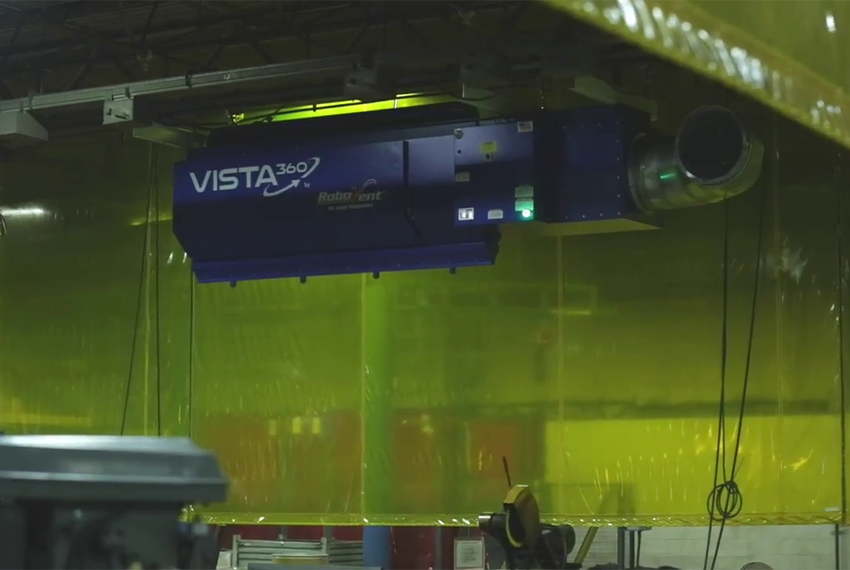

Featured Solution: Vortex

Industries: General Fabrication

Applications: Grinding, Laser Cutting, Manual Welding, Metalworking, Robotic Welding

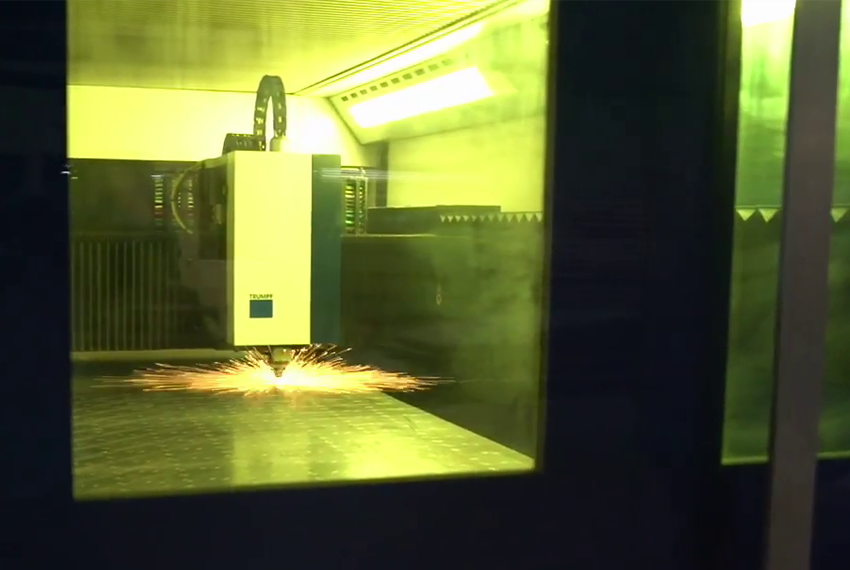

When Tru-Form Steel & Wire began using state-of-the-art laser equipment in their metalworking facility, they knew they needed to make some changes in air quality. With eight robotic welding cells and forty manual welding, grinding or cutting stations, there was a lot of dust and smoke in the air. The company contacted RoboVent, and, a short installation later, their air quality radically began to improve.

Cleaner air is also making equipment work better at Tru-Form Steel & Wire. Dirt and dust are detrimental to electronics, and the company’s cutting-edge metalworking equipment is now working more smoothly.