Plumbers & Pipefitters Local 495: Getting Weld Fume Under Control

Featured Solution: Senturion

Other Solutions: Fume Arms, Fusion

Industries: Workforce Education

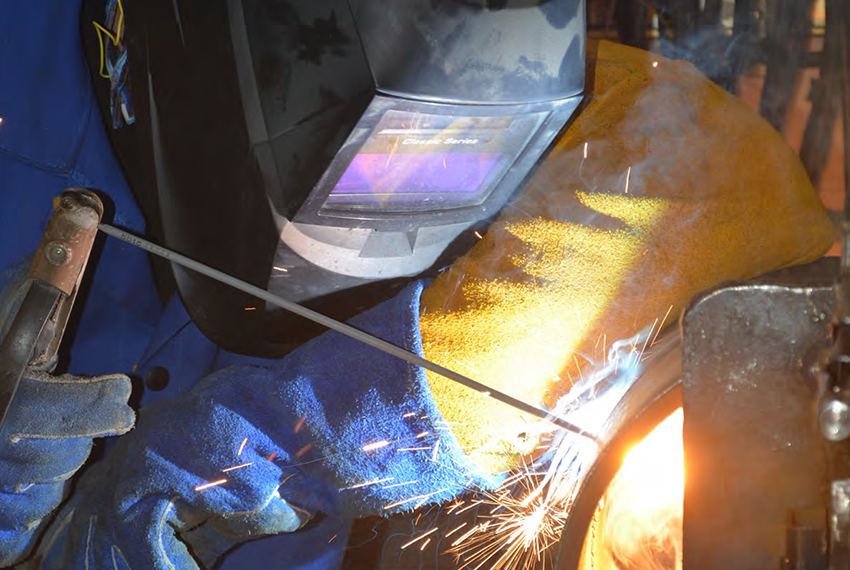

Applications: Manual Welding

Plumbers & Pipefitters Local 495 is a training facility designed to educate Union members in the skill and art of welding. This facility is located in Cambridge, Ohio and operates year round. The majority of training in the 20 weld booths takes place between August and May, but there are students honing their skills Monday through Friday throughout the year.

The Problem: Rising Costs of Weld Fume Collection

The Problem: Rising Costs of Weld Fume Collection

The Local 495 training program hosts several classes per day in order to teach students the fundamentals of the welding process. There are 20 weld booths where students can master their craft. The ongoing welding requires a fume collection system to facilitate a safe training environment.

With their previous system, training took place with little thought or interruption. However, the Training Department began to notice that the system they had in place, while working properly, was beginning to become very expensive to maintain. Local 495 had a setup of one capture system per two weld booths. This was leading to costly filter replacement expenditures.

The Local 495 Training Department knew that they needed to make a decision. It just so happened that their gas and consumable supplier, Airgas, is one of RoboVent's leading partners. The reps at Airgas suggested that Mr. Young place a call to one of the Solutions Directors at RoboVent.

The RoboVent Weld Fume Collection Solution

The RoboVent Weld Fume Collection Solution

Director of the training program, Jim Young, reached out to us with a need to control maintenance costs and reduce filter replacement expenses. After making a visit to the training facility, the RoboVent Solutions Director suggested reducing the amount of collectors. He recommended moving to one centralized system that would meet the collection requirements of all 20 welding booths. This system would connect 20 fume arms with ducts to one large collector. With the fume arms in place, the system was successfully able to capture the weld fumes while reducing the filter replacement needs.

The Result

The Result

After our specialized installation team fitted the training facility with the RoboVent solution, Mr. Young immediately recognized an improvement. While the previous system was capable of removing the fumes to a safe level, it produced an uncomfortable volume of noise. The RoboVent solution placed the vacuum system outside the facility, effectively eliminating any background noise that would hinder the training process. Mr. Young is very satisfied that RoboVent was able to provide them with a solution that was “cleaner, quieter, and provided him with the ability to better instruct his students.”