The Single Most Effective Tip for Collecting Oil Mist

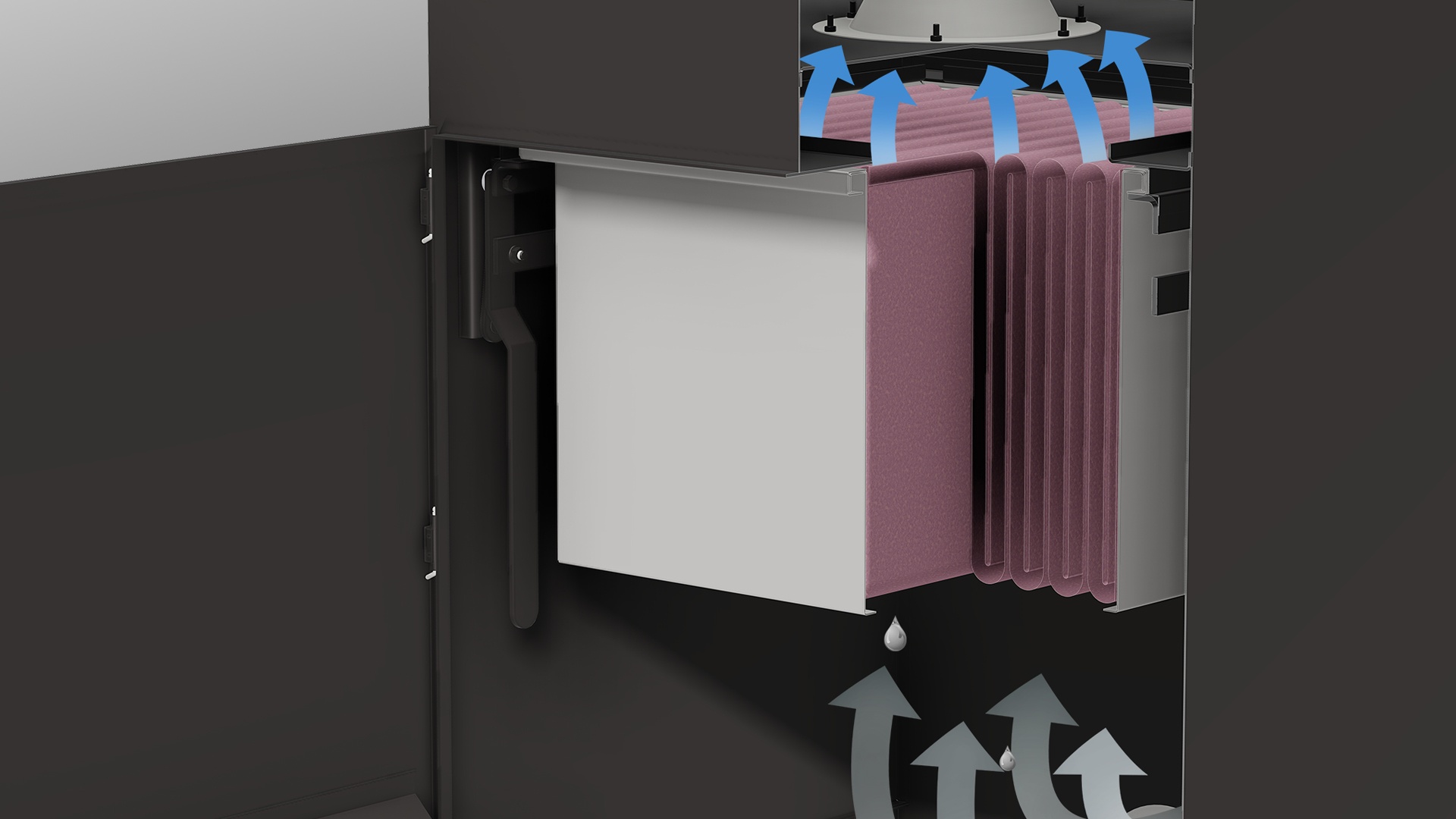

The best filter to use to collect oil mist is called a packed-bed, or coalescing, filter. A packed-bed filter pulls oil out of the air and allows the oil to drain off. This filter works even when saturated, whereas normal filter media becomes soaked and much less effective. Ideally, the filter will have specially formulated media that lets the oil collect and drain into a basin.

A packed-bed filter has several major benefits, including:

- The ability to pull even the finest oil mist out of the air

- The ability to drain the oil off of the filter

- A long life span, due to the filter’s ability to shed oil and remain in operation

- Major costs savings, due to long filter life and low maintenance

Understanding how to filter oil mist from the air is more important than ever. As manufacturing increases and becomes more competitive, it is vital to protect workers and equipment from the harmful effects of oil mist. The health effects of exposure are well documented and can result in conditions ranging from asthma to cancer. Oil mist can damage equipment, as well, if it is allowed to accumulate and seep into electronics and other sensitive components. Oil mist poses a common slip-and-fall risk, as well, if not addressed in a serious way.

Fortunately, many solutions exist to collect oil mist. These include the RoboVent Clarion™ Series of collectors, units specifically designed to pull oil mist out of the air. RoboVent also produces packed-bed filters that come in three different sizes and two different efficiency levels.

To learn more about the dangers of oil mist and how to address them, check out this article.

Contact Us With Your Questions!

SUBSCRIBE TO

BLOG UPDATES