Managing Hydrocarbon Buildup in Dust Collection Systems

Managing hydrocarbon buildup in dust collection systems is a major challenge for metal stamping operations and other industries using lubricants and metalworking fluids (MWFs). Over time, hydrocarbon residues can coat filter media and reduce system efficiency. These tips will help you manage hydrocarbon residues, extend filter life and improve the performance of your dust collection system.

The Hydrocarbon Problem

Oily residues from stamped parts can turn into sticky hydrocarbon buildup on dust collector filters when those parts are later welded or cut—reducing filter life and system performance.

Hydrocarbons are organic compounds composed of hydrogen and carbon atoms, commonly found in oils, lubricants and rust prohibiters. These fluids are widely used in metalworking operations to reduce friction and heat during metal shaping and cutting.

During thermal processes such as welding, brazing, soldering, stamping, laser cutting, and grinding, oils and lubricants vaporize or aerosolize, creating polycyclic aromatic hydrocarbons (PAHs). Vaporized hydrocarbons mix with fumes and metal dust, creating sticky, fine particulate mixtures. The resulting hydrocarbon-laden fumes can be challenging to capture and filter. This process creates several problems in the dust collection system:

- Vaporized hydrocarbons condense on surfaces and filter media, creating sticky, hard-to-remove residues.

- The combination of sticky hydrocarbons and fine dust plugs filter media, leading to rapid clogging and reduced airflow.

- Clogged filters have higher pressure drop. In addition to driving up energy consumption, this reduces airflow, allowing fumes to escape at the capture point.

The result is dramatically shortened filter life and increased maintenance time and costs. Excess hydrocarbon buildup requires more frequent maintenance, including filter changes and cleaning, driving up operational costs and downtime.

Unmanaged hydrocarbons also present health and safety risks for workers. Hydrocarbon fumes can pose respiratory hazards to workers and contribute to poor indoor air quality.

Sources of PAHs in Industrial Processes

Welding and thermal cutting processes release polycyclic aromatic hydrocarbons (PAHs) and other contaminants that can accumulate in dust collection systems.

Polycyclic aromatic hydrocarbons (PAHs) are a group of organic compounds composed of multiple fused aromatic rings. They are formed primarily through the incomplete combustion of organic materials, including oils, lubricants, certain kinds of coatings, and oil-based antispatter fluids. These materials may be plant, animal (fatty acid) or mineral (petroleum) based.

Welding, stamping and other metalworking processes form PAHs when oils and lubricants in the air or on metal surfaces vaporize and undergo thermal decomposition, creating PAHs as byproducts. Sources of PAHs in metalworking include:

- Welding Processes: During welding, intense heat vaporizes hydrocarbons from oils, lubricants, or coatings on the metal surface. The thermal breakdown of these compounds generates PAHs, which are emitted as part of the weld fumes.

- Thermal Cutting (Plasma and Laser): Plasma and laser cutting rely on focused heat to cut through metal. When the workpiece is coated with oil or grease, the high temperatures vaporize these substances, leading to the formation of PAHs in the resulting fumes.

Handling Hydrocarbons

Managing hydrocarbons in dust collection systems often requires a multifaceted approach. By reducing hydrocarbon emissions at their origin, optimizing airflow, and implementing pre-filtration and pre-coat strategies, facilities can minimize the impact of sticky residues and fine particulates on their systems. These methods not only enhance filter performance but also extend system longevity and improve workplace air quality. Here are key strategies for effectively managing hydrocarbons.

Remove the Source

Eliminating or reducing the source of hydrocarbons is the most direct way to manage their impact on dust collection systems. By addressing the problem at its origin, facilities can reduce the burden on their dust collection systems and improve overall air quality. This can involve:

- Minimizing the use of hydrocarbon-based lubricants and oils in processes like stamping, welding or machining.

- Switching to low-viscosity or water-soluble alternatives.

- Pre-cleaning workpieces to remove excess oils before welding or other thermal processes.

Adjust Air-to-Cloth Ratio

A lower air-to-cloth ratio (i.e., more filter media per CFM of airflow) can help to extend filter life when dealing with challenging hydrocarbon-laden particulate. Talk to your dust collection system designer to see if this strategy is recommended for your application.

Use Pre-Filtration

Pre-filtration devices capture larger hydrocarbon droplets and particles before they reach the main filters in the cartridge dust collector. These can include wire mesh, baffles and roughing filters.

- Wire mesh and baffle systems are designed to deflect and capture larger hydrocarbon droplets and particles. Installed upstream of the primary filters, these systems capture a portion of the fume and dust, preventing them from reaching the main dust collector cartridge filters. Mesh and baffle systems also act as a spark arrestor, adding a layer of safety while reducing filter clogging.

- Roughing filters are an effective defense against hydrocarbons and PAHs in dust collection systems. These coarse filters capture larger droplets and particles before they reach the primary filters, reducing the load and preventing sticky residues from clogging finer filter media. Roughing filters are typically disposable, simplifying maintenance and protecting more expensive cartridge filters and extending their lifespan.

Hydrocarbon buildup from oil, mist, and antispatter in stamping operations can form a sticky film on dust collector filters, drastically reducing airflow and requiring more frequent filter changes.

Add a Pre-Coat

Applying a filter pre-coat material like expanded perlite to filter media creates a protective barrier that captures hydrocarbons and PAHs before they embed into the filter fibers. This layer of powdered material protects filter media by binding with PAHs and sticky, moist dust, enabling it to be pulsed off efficiently. Pre-coating is especially beneficial in operations with persistent hydrocarbon challenges, such as welding or stamping with oil-based lubricants. The porous structure of expanded perlite absorbs sticky residues and fine particles, extending the life of filters. By incorporating pre-coat into the dust collection system, facilities can better handle hydrocarbons without compromising performance.

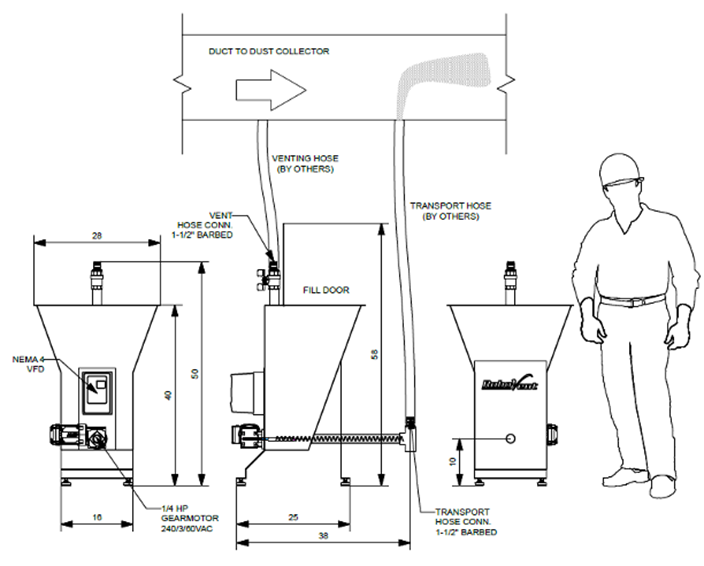

A pre-coat system introduces a dry, inert material into the airstream to coat filter surfaces—reducing hydrocarbon buildup and protecting filter media.

Cleaning and Maintenance

Regular cleaning and maintenance are essential for managing hydrocarbon buildup and ensuring the efficiency, safety and longevity of your dust collection system. That includes steps such as:

- Ensure the filter pulsing system is functioning properly and keep the system clean and maintained.

- Regularly inspect filters for signs of clogging, saturation or damage.

- Replace filters promptly when pressure drop exceeds recommended levels to maintain airflow and system efficiency.

Need Help Managing Hydrocarbons?

Hydrocarbon buildup doesn’t have to disrupt your operations. With RoboVent’s expertise in dust collection system design and filtration solutions, we can help you tackle even the toughest challenges. Whether it’s selecting the right filters, integrating pre-coat strategies, or optimizing airflow and pre-filtration, our team will create a solution tailored to your needs.

Contact us today and learn how we can enhance your system’s performance, protect your equipment, and maintain a cleaner, safer work environment.

Contact Us With Your Questions!

SUBSCRIBE TO

BLOG UPDATES