Extending the Life of Your Dust Collector Cartridge Filters

Industrial air cartridge filters play a crucial role in maintaining air quality within industrial environments. Their primary function is to capture dust, fumes, and other particulate matter, thereby ensuring that the air remains clean and safe for both machinery and workers. Like all filters, however, they have a limited lifespan. If not maintained or used correctly, their efficiency can decline, leading to a range of operational and health issues. These tips will help you optimize filter life for your cartridge dust collector.

1. Invest in Quality Filters from the Start

Not all cartridge filters are created equal. Investing in high-quality filters can make a significant difference in longevity. Opt for filters that are made with robust materials and quality construction. High-quality dust collector cartridge filters like PleatLock™ cartridge air filters can significantly extend the life of your dust collector filters and reduce maintenance intervals. Look for air cartridges with high-quality filter media, consistent pleat spacing, sturdy construction of pleats and end caps, and robust gaskets and seals to maximize filter life and minimize the risk of leaks past the filter. High-quality filter cartridges may cost a bit more up front, but will last much longer, saving money and time in the long run.

Not all cartridge filters are created equal. Investing in high-quality filters can make a significant difference in longevity. Opt for filters that are made with robust materials and quality construction. High-quality dust collector cartridge filters like PleatLock™ cartridge air filters can significantly extend the life of your dust collector filters and reduce maintenance intervals. Look for air cartridges with high-quality filter media, consistent pleat spacing, sturdy construction of pleats and end caps, and robust gaskets and seals to maximize filter life and minimize the risk of leaks past the filter. High-quality filter cartridges may cost a bit more up front, but will last much longer, saving money and time in the long run.

2. Choose the Right Filter Media for Your Application

Different kinds of filter media require different types of filters—heavy, abrasive dust will require a different type of cartridge than ultrafine dust or sticky, hygroscopic dust. Selecting the best cartridge filter media for your specific application will improve filter life and performance. Special filter coatings, such as PTFE-coated cartridge filters, can help filters shed wet or sticky dust and withstand exposure to corrosive chemicals. Talk to a filter specialist for help in selecting the right filter media.

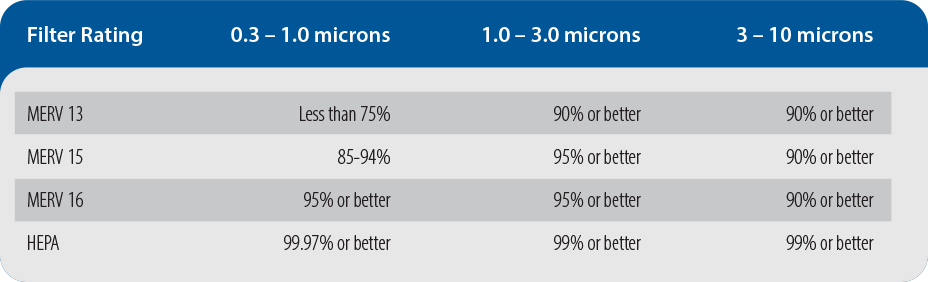

3. Understand MERV Ratings

Most dust collector cartridge filters are rated using the Minimum Efficiency Reporting Value (MERV) rating system. The MERV rating is an indicator of how well the filter media can capture particles in different size ranges (3.0-10 microns, 1.0 to 3.0 microns, and 0.3 to 1.0 microns). Filters with higher MERV ratings capture more of the smaller particulate. Consider the particle size distribution of the particulate you want to capture as well as the air quality you want to achieve. When it comes to filter life, there is a tradeoff between filtration efficiency and filter lifespan, as well as pressure drop and energy use. A higher MERV rating means the filter can capture more of the finer particulate, but also will result in faster filter loading and a shorter lifespan. Keep in mind that as dust accumulates on the filter media, most cartridge filters will eventually reach a filtration efficiency close to MERV 16. But for filtering fine and potentially dangerous particles, it is still important to choose a filter that will provide the right filtration efficiency out of the box.

4. Use a Filter Pulsing System

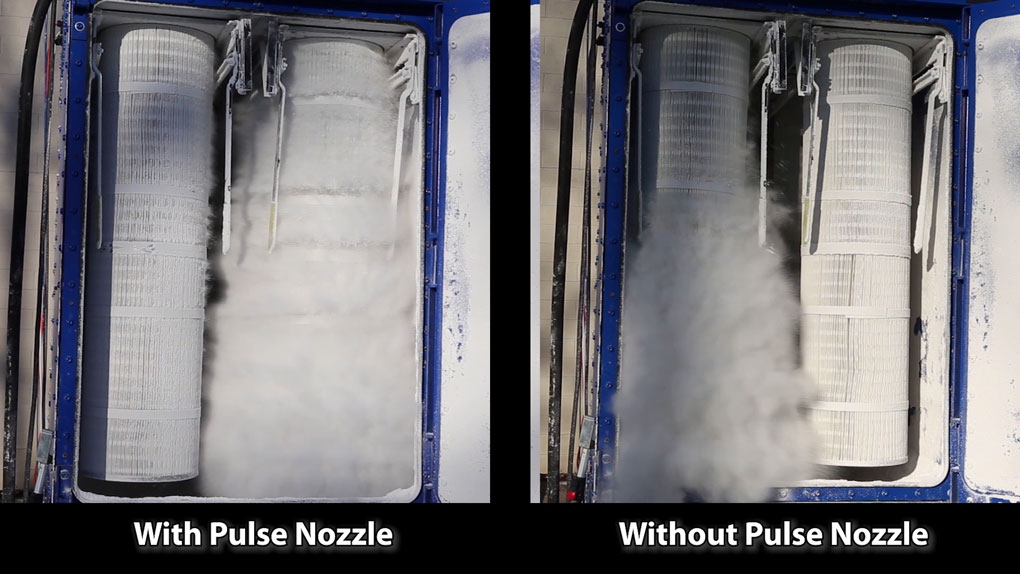

A filter pulsing system, commonly known as a reverse pulse-jet cleaning system, significantly enhances the longevity of dust collector cartridge filters. By directing compressed air in the reverse direction of standard airflow, this system efficiently dislodges accumulated particulates from the filter’s surface and into the collection bin. This periodic cleaning maintains optimal airflow and system efficiency, ensuring that filters remain effective for longer periods. When calibrated correctly, a filter pulsing system can offer substantial cost savings by prolonging filter life, reducing maintenance, and enhancing overall dust collector performance. Look for a filter pulsing system that cleans the entire length of the filters efficiently. Pulsing frequency should be calibrated to the dust load, ensuring the system pulses often enough to maintain optimal airflow but not so frequently as to cause undue wear on the filters. Some pulsing systems automatically adjust the pulsing frequency based on differential pressure (pressure drop) across the filters (a measure of filter loading).

A filter pulsing system, commonly known as a reverse pulse-jet cleaning system, significantly enhances the longevity of dust collector cartridge filters. By directing compressed air in the reverse direction of standard airflow, this system efficiently dislodges accumulated particulates from the filter’s surface and into the collection bin. This periodic cleaning maintains optimal airflow and system efficiency, ensuring that filters remain effective for longer periods. When calibrated correctly, a filter pulsing system can offer substantial cost savings by prolonging filter life, reducing maintenance, and enhancing overall dust collector performance. Look for a filter pulsing system that cleans the entire length of the filters efficiently. Pulsing frequency should be calibrated to the dust load, ensuring the system pulses often enough to maintain optimal airflow but not so frequently as to cause undue wear on the filters. Some pulsing systems automatically adjust the pulsing frequency based on differential pressure (pressure drop) across the filters (a measure of filter loading).

5. Use Vertical Alignment for Dust Collector Cartridge Filters

Vertical alignment in dust collector cartridge filters offers distinct advantages in extending filter life, especially for applications with heavy dust (such as powder & bulk). When filters are vertically aligned, gravity assists in the natural downward movement of collected particulates, preventing excessive dust accumulation on the filter’s upper sections. This uniform distribution of dust across the filter media reduces localized clogging, ensuring more consistent airflow and reducing the strain on any single part of the filter. Furthermore, during cleaning cycles, dislodged particles can exit the filter more easily due to this vertical orientation, leading to more effective filter cleaning and prolonged efficiency. Dust collectors designed for vertical cartridge filter alignment, such as RoboVent Senturion, can help extend filter life. Horizontal filters, such as those used in RoboVent Spire, are best for applications such as weld fume extraction that do not produce significant amounts of surface dust on the filters.

6. Protect Cartridge Filters

When collecting coarse, heavy or abrasive dust, elements such as drop-out boxes or baffle systems can significantly reduce wear and tear on cartridge filters, extending their usable life and preventing leaks past the filters. Drop-out boxes use gravitational forces to allow heavier particles to fall out of the airstream into a collection bin before reaching the filter chamber. Baffle systems redirect the airflow, causing larger particles to lose momentum and drop out of the airstream. For very heavy dust loads, a progressive filtration strategy may be recommended. For example, a less-expensive (and more frequently changed) intake filter may be used to remove larger dust before it hits more expensive filter cartridges. In some cases, a different style of dust collector, such as a cyclone collector, is used as a pre-filter to remove heavier particles before air reaches the cartridge dust collector. If sparks are produced near the dust collector intake (for example, by welding or grinding), install a spark arrestor to prevent sparks from reaching the filters and causing a dust collector fire.

7. Optimize the Dust Collector’s Operation

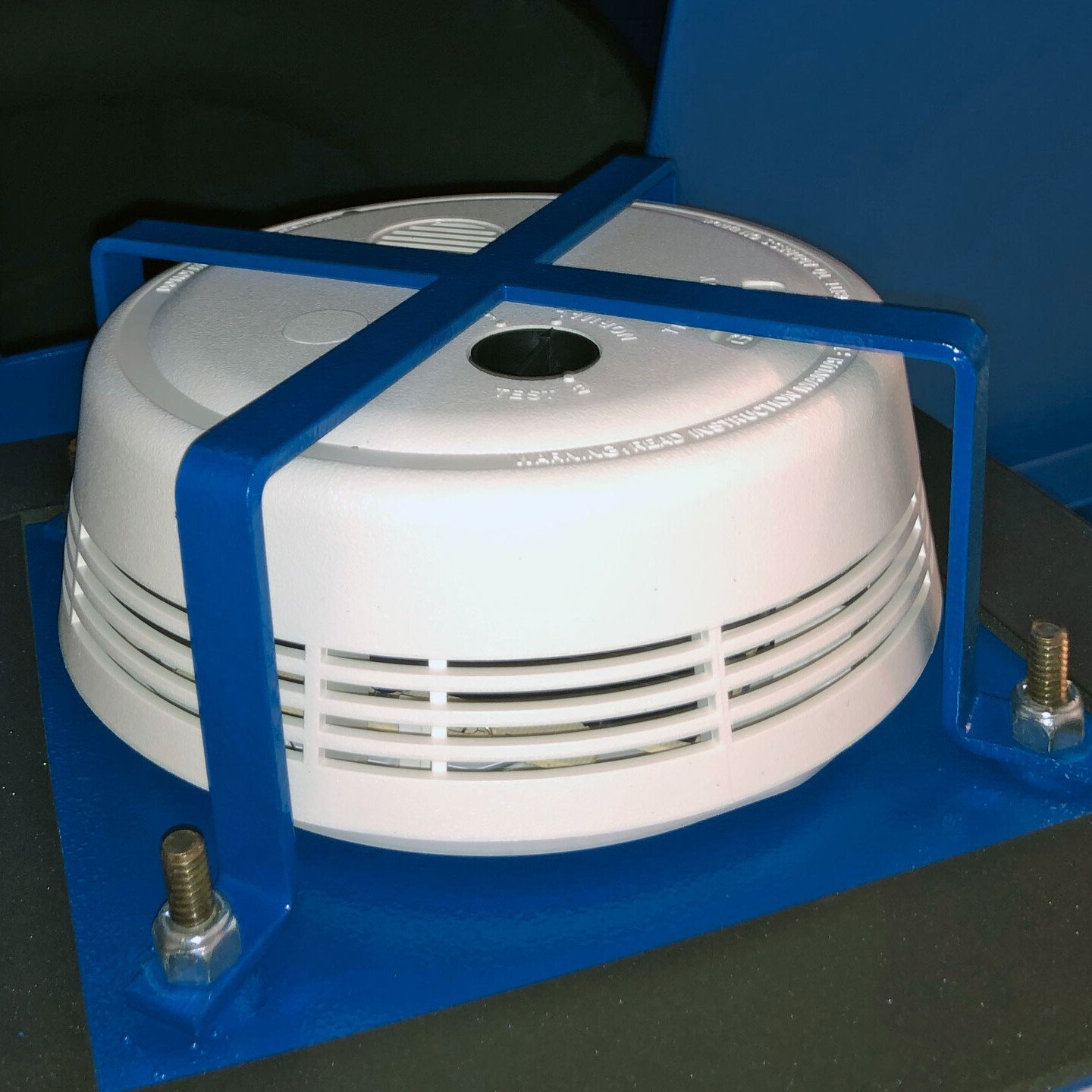

Regular dust collector preventive maintenance and proper operation are critical to ensure consistent performance and a safe working environment. Ensure that the dust collector operates within the recommended parameters and has been appropriately sized for the application, including CFM and air-to-cloth ratio. Overloading the system or running it at capacities beyond its design can wear out the filters quickly. Periodically check for air leaks and ensure that the system’s seals are intact. A sensor such as the SafeSensor™ Particulate Monitor can help to detect leaks past the filters. Empty the dust bin or tray when it becomes full (a bin monitor can help you keep an eye on dust levels). The dust collector and filter chamber should also be cleaned on a regular basis so that dust and grime do not build up inside the chamber or dust collector intake.

8. Maintain a Suitable Environment for the Dust Collector

Extremes in temperature and humidity can affect the performance and lifespan of dust collector cartridge filters. If possible, install your dust collection system in an area where environmental conditions are stable. If the system is outdoors, provide shielding or housing to protect it from the elements. Insulation can also help to reduce condensation of moisture inside the dust collector, which can damage filter media and cause clogging. Ensure proper ventilation around the dust collector to prevent heat build-up, which could affect the system’s performance. Avoid exposing the filters to chemicals or oils that can degrade the filter material.

9. Store Filters Properly

If you have spare filters on hand, store them correctly. Keep them in a dry, cool place away from direct sunlight. Improper storage can lead to premature degradation, even before the filter is installed.

10. Change Cartridge Filters When Necessary

While extending the life of your filters is beneficial, it’s also essential to recognize when they’re past their prime. Operating with worn-out filters not only reduces the efficiency of your dust collector but can also pose health risks. Know the typical lifespan of your filters and replace them when they reach the end of their service life. Regularly inspect filters to look for signs of wear, damage, or excessive clogging, and change filters when they have reached the end of their life.

Cartridge air filters should be changed annually at an absolute minimum, or more frequently based on the manufacturer’s recommendations and your actual dust load. For heavy load applications or moist/sticky dust, filters may need to be changed more often. Monitoring the differential pressure across the filters provides a real-time indication of filter health. As dust accumulates, this pressure will increase, signaling that a filter change or cleaning may be necessary. Especially in environments with variable dust loads, being responsive to these pressure changes is crucial. Adjusting your maintenance schedule based on both the application specifics and actual dust load can extend filter life, optimize system performance, and reduce operational costs. Read more: How Often Should You Change Dust Collector Filters?

Need help with dust collector maintenance or filter selection? Talk to a Solutions Specialist!

Contact Us With Your Questions!

SUBSCRIBE TO

BLOG UPDATES