Industrial Cartridge Filters vs. Baghouse Filters: What’s the Difference?

Baghouse filters and cartridge filters are both prominent solutions for industrial air filtration. However, they have distinct designs, functions, and advantages depending on the application. Let’s delve into their differences.

Dust Collector Cartridge Filters

Cartridge air filters are used for cartridge-style industrial dust collectors. A cartridge dust collector works by drawing dust-laden air into the system, where it passes through cylindrical cartridge filters. As the air flows through these filters, dust particles are trapped on the exterior surface of the cartridges. As dust accumulates, excess dust is pulsed off the filter using a pulse-jet cleaning mechanism, ensuring the filter remains efficient and the airflow remains consistent. The dislodged dust then settles into a collection system for proper disposal or recycling.

Cartridge air filters are used for cartridge-style industrial dust collectors. A cartridge dust collector works by drawing dust-laden air into the system, where it passes through cylindrical cartridge filters. As the air flows through these filters, dust particles are trapped on the exterior surface of the cartridges. As dust accumulates, excess dust is pulsed off the filter using a pulse-jet cleaning mechanism, ensuring the filter remains efficient and the airflow remains consistent. The dislodged dust then settles into a collection system for proper disposal or recycling.

Cartridge filters are highly versatile and come in a range of filtration efficiencies and media types, making them suitable for a wide variety of dust collection applications.

View our cartridge filter catalog.

Design

Cartridge filters are cylindrical in shape and are much more compact than bag filters. Dust-laden air is directed through the filter media, capturing particles as the air passes through. The pleated media design allows for a large area of filter media to be packed into a small space. As a result, cartridge dust collectors are usually smaller overall than baghouse dust collectors with the same airflow (CFM) rating.

Media/Materials

Cartridge filters often make use of advanced and specialized materials due to their design and intended applications. Common media include pleated paper (cellulose) for basic applications, but they frequently feature advanced synthetic materials like spunbond polyester, cellulose/poly blends, nanofiber, and PTFE-coated media. Some cartridges have enhancements like oleophobic, anti-static, or flame-retardant treatments. The broad range of media types with different filtration efficiencies and properties makes cartridge dust collector filters highly versatile and suitable for a broad range of applications, from heavy abrasive dust to ultrafine dust.

Cleaning Mechanism

Cleaning Mechanism

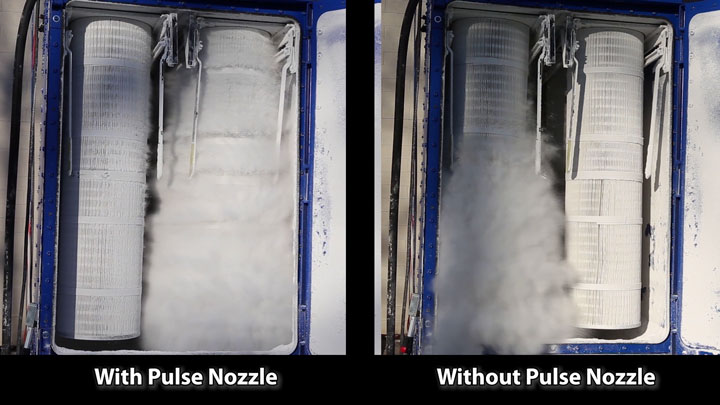

Cartridge filters commonly use a pulse-jet cleaning mechanism. Compressed air is periodically blasted through the filters in the reverse direction, knocking dust off the filter’s exterior. This dust then falls into a collection system.

Applications

Applications

Cartridge filters are ideal for a wide range of applications, especially those with smaller dust particles and requiring high filtration efficiency. They’re commonly found in welding, metalworking, food processing, pharmaceutical manufacturing, woodworking, and many other industries and applications.

Advantages

- Compact design, requiring less space and enabling an overall smaller and more energy-efficient dust collection system.

- High filtration efficiency, especially for fine particles.

- Variety of media types for a diverse range of applications.

- Easier to replace than bag filters.

Baghouse Filters (Fabric Filters)

Baghouse filters (also known as fabric filters, envelope filters, jet filters or sock filters) are used for baghouse-style dust collectors. A baghouse dust collector works by pulling dust-laden air into the system and directing it through long fabric bags. As the air travels from the outside of these bags to the inside, dust particles are captured and held on the outer surface of the bags. As the dust layer builds up, the collector employs a cleaning mechanism—either a mechanical shaking action or a reverse airflow burst—to shake off or blow away the accumulated dust from the bags’ surfaces. This dislodged dust then falls into a hopper or collection system at the base of the baghouse for subsequent disposal or recycling.

Baghouse filters (also known as fabric filters, envelope filters, jet filters or sock filters) are used for baghouse-style dust collectors. A baghouse dust collector works by pulling dust-laden air into the system and directing it through long fabric bags. As the air travels from the outside of these bags to the inside, dust particles are captured and held on the outer surface of the bags. As the dust layer builds up, the collector employs a cleaning mechanism—either a mechanical shaking action or a reverse airflow burst—to shake off or blow away the accumulated dust from the bags’ surfaces. This dislodged dust then falls into a hopper or collection system at the base of the baghouse for subsequent disposal or recycling.

Baghouse filter shape, size and design vary considerably based on the specific type of baghouse dust collector.

Design

Baghouse filters, as their name implies, use long bags (often made of woven or felted fabric) as the filtering medium. The bags are typically suspended vertically in a large housing, and dust-laden air passes through the bags from the outside to the inside, leaving the dust behind on the outside of the bags. Depending on the type of baghouse collector, the baghouse filters may be long, narrow and sock-like or shorter and wider. Some fabric filters, called envelope filters, are shaped like large flat envelopes; these are usually arranged horizontally. In some types of bag collectors, baghouse filter cages are used to provide additional support to the filters. These consist of a series of vertical wires, often made of stainless or galvanized steel, held apart by a series of horizontal rings.

Media/Material

Baghouse filters traditionally use woven or felted fabrics. Common materials include cotton, polyester, acrylic, aramid (like Nomex), and fiberglass. These fabrics can be treated or finished to enhance their filtration performance and durability, such as singed, glazed, or PTFE membrane treatments. The choice of fabric often depends on the temperature, chemical nature, and size of the dust particles in the application.

Cleaning Mechanism

Over time, dust accumulates on the bag’s exterior, forming a dust cake. Periodically, the bags are cleaned using a burst of reverse airflow or a mechanical shaking mechanism, which dislodges the accumulated dust. This collected dust then settles into a hopper for removal. Baghouse dust collectors are divided into different types based on their filter cleaning mechanism: e.g., pulse jet baghouse, reverse air or reverse jet baghouse and shaker baghouse dust collectors.

Applications

Baghouse dust collectors are often used for handling very high air volumes, extremely heavy dust loads, and high temperatures. Common applications include cement production, power plants, and steel mills.

Advantages

Advantages

- Can handle high dust loads.

- Suitable for very large air volume and high-temperature applications.

- Available in various fabric materials for different applications.

Cartridge Filters vs. Baghouse Filters: A Comparative Guide

The choice between baghouse filtration and cartridge filtration should be based on the specific requirements of the application, including the type and volume of dust, available space, desired filtration efficiency, and budget considerations.

Filtration Efficiency

Cartridge filters typically offer higher filtration efficiencies, particularly for fine dust particles. Their pleated design maximizes the surface area, which aids in capturing even micron-sized particles. However, baghouse filters can be highly effective for larger particles and heavier dust loads. Baghouse filters are typically used for larger particles, though they can be outfitted with specialty media to improve their efficiency with finer particulates.

Footprint

Cartridge dust collectors, due to the compact design of pleated cartridge filters, require less space than baghouses, making them ideal for facilities with space constraints. Additionally, the design of cartridge filters, as opposed to the longer bag filters, means that they can fit into tighter spots while still maintaining effective airflow. This adaptability can be a significant advantage when retrofitting or upgrading in limited spaces.

Maintenance

While both types of dust collector filters require periodic replacement to maintain airflow and efficiency, cartridge filters are often easier to replace than bag filters. Many cartridge filters can be easily replaced with minimal or no tools without entering the filter chamber, making filter replacement fast, easy, safe and clean. Baghouse filter replacement, on the other hand, is often a complex and messy affair. This translates to lower maintenance costs and time for cartridge filter replacement vs. baghouse filter replacement.

Longevity

Depending on the application and dust type, bag filters may have a longer lifespan than cartridge filters. However, with advancements in filter media technology, high-quality modern cartridge filters offer extended service lives. Filter lifespan and maintenance intervals for both types of dust collection filters are highly dependent on dust volume and characteristics, media type and coatings, air-to-cloth ratio, the operating environment (e.g., temperature, humidity, chemical exposure), and other aspects of dust collection system design. Proper media selection and filter maintenance will extend the life of dust collector filters.

Cost

Both cartridge filters and baghouse filters are consumable, and filter replacement costs must be considered as part of the overall lifetime cost of ownership for the dust collector. Bag filters are typically less expensive per unit than cartridge filters. The specific cost can vary based on the material, size, and any special treatments or coatings. However, cartridge dust collectors can offer energy savings and other advantages that offset the costs of consumable dust collector filters.

Both cartridge filters and baghouse filters are consumable, and filter replacement costs must be considered as part of the overall lifetime cost of ownership for the dust collector. Bag filters are typically less expensive per unit than cartridge filters. The specific cost can vary based on the material, size, and any special treatments or coatings. However, cartridge dust collectors can offer energy savings and other advantages that offset the costs of consumable dust collector filters.

Looking for High-Quality Dust Collector Filters?

RoboVent stocks a wide selection of dust collector filters, including both cartridge air filters and baghouse filters. We even manufacture our own aftermarket cartridge dust collector filters for virtually any make and model of dust collector.

Contact Us With Your Questions!

SUBSCRIBE TO

BLOG UPDATES