DUST AND FUME COLLECTION CHALLENGES IN THE AEROSPACE AND AVIATION INDUSTRY

A facility producing airplanes or their parts includes many processes that might produce air quality challenges.

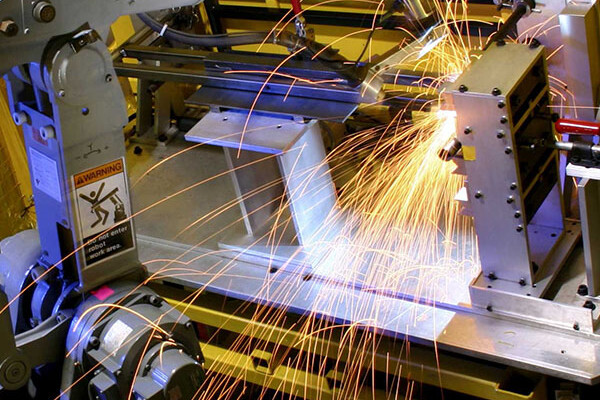

Metal-cutting tables, welding stations and robotic welding cells create serious amounts of dust and fumes that can be an

acute problem for worker health.

Dust coming off a cutting table creates an inhalation hazard for workers, as well as an ignition risk if the dust is

allowed to build up. As dangerous as this dust is, it is perhaps surpassed by weld fumes. These fumes contain

particulates that measure less than a micrometer across. The small size of these particles makes it easier for them to

travel deeply into the lungs if inhaled.

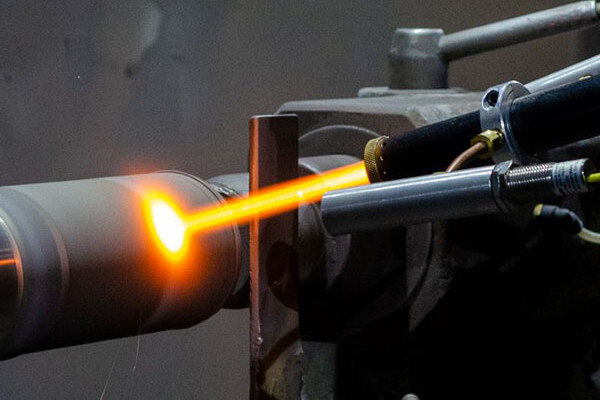

Metallic dust and weld fumes often contain toxic metals, many of which have extremely serious health

consequences for workers. For example, hexavalent chromium is produced by many welding processes. This

substance is a known carcinogen and a cause of other serious health problems, as well. The Occupational

Safety and Health Administration (OSHA) has a specific regulation for this substance, as well as for many

other specific toxic metals. Manufacturing facilities need a comprehensive dust and weld fume control system

to deal with these issues.

Besides toxicity, fire hazard is another danger that comes from dust. The Bureau of Labor Statistics

estimates that about 3% of workplace fatalities result from fires and explosions. A high-quality dust

collection system is needed to prevent a buildup of dust. The best collectors also include spark arrestance

systems to stop fires before they start.

With aircraft and parts production lines moving as fast as they are, it is important for manufacturers to

attract and retain the best workers. The American Welding Society estimates that manufacturing will see a

shortfall of 290,000 skilled welders by 2020. Maintaining a clean, attractive and safe workplace—one free

from airborne dust and haze—is essential in keeping a factory staffed with the best workers.

High-quality air filtration is necessary for complying with air quality regulations, as well. OSHA sets

standards related to air quality. Permissible exposure limits (PELs) dictate how much of a substance can

exist in a worker’s breathing zone over an eight-hour time-weighted average (TAV). Highly toxic substances

such as hexavalent chromium and manganese have their own limits.

Related Resources

SOLUTIONS FOR DUST AND FUMES IN THE AEROSPACE AND AVIATION INDUSTRY

RoboVent’s air quality solutions are suited for this industry and its high standards of performance. Our dust collectors make your facility safer, healthier and more efficient—while working within your space and budget constraints. We’ve put a lot of thought into details like space-saving design, integrated fire safety and automated controls that let your fume and dust collectors practically take care of themselves.

RoboVent’s collectors feature automated systems that ensure they run only when needed. This cuts operating costs and lengthens filter life. A manufacturer can’t afford the downtime that might come from a failed dust collector, so reliability and easy maintenance have been built into RoboVent equipment. With advanced control systems, plant managers can move beyond preventative maintenance to truly predictive maintenance.

CONTACT US

Contact one of our industrial dust experts to gain the advantage against dust-generating processes and applications.