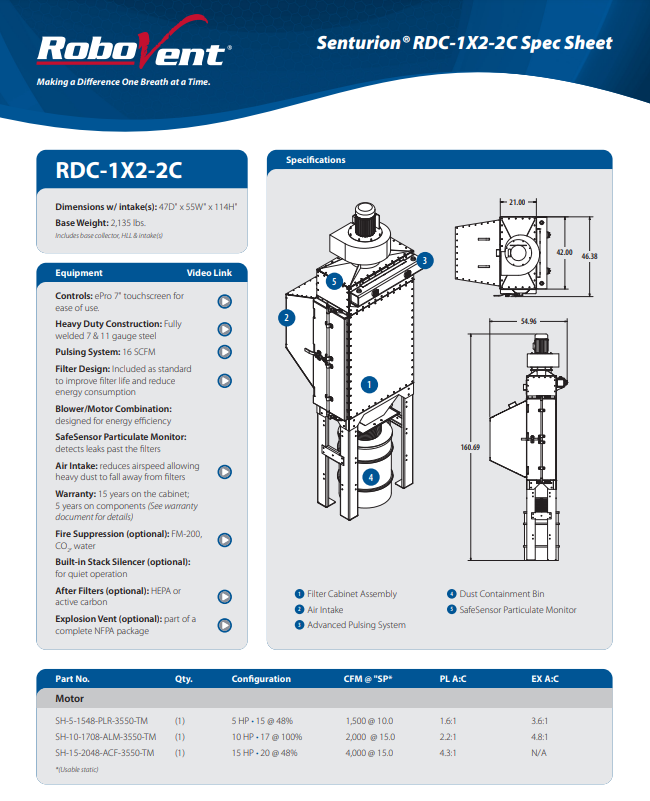

Senturion Modular Dust Collector

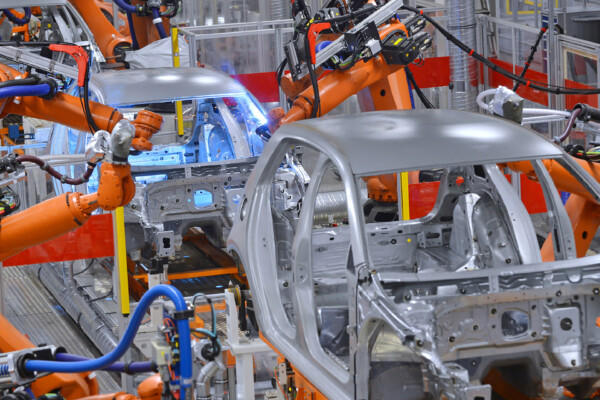

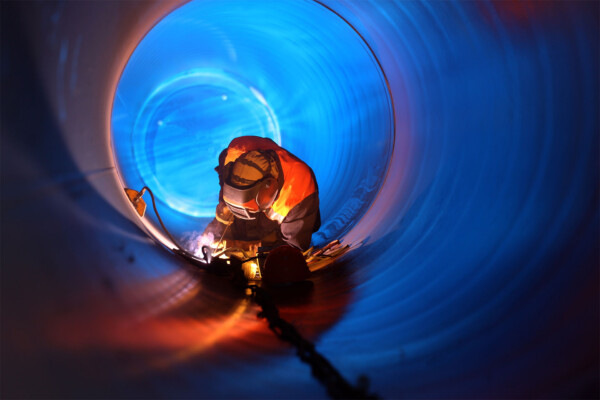

ONE TOUGH DUST COLLECTOR. COUNTLESS APPLICATIONS.

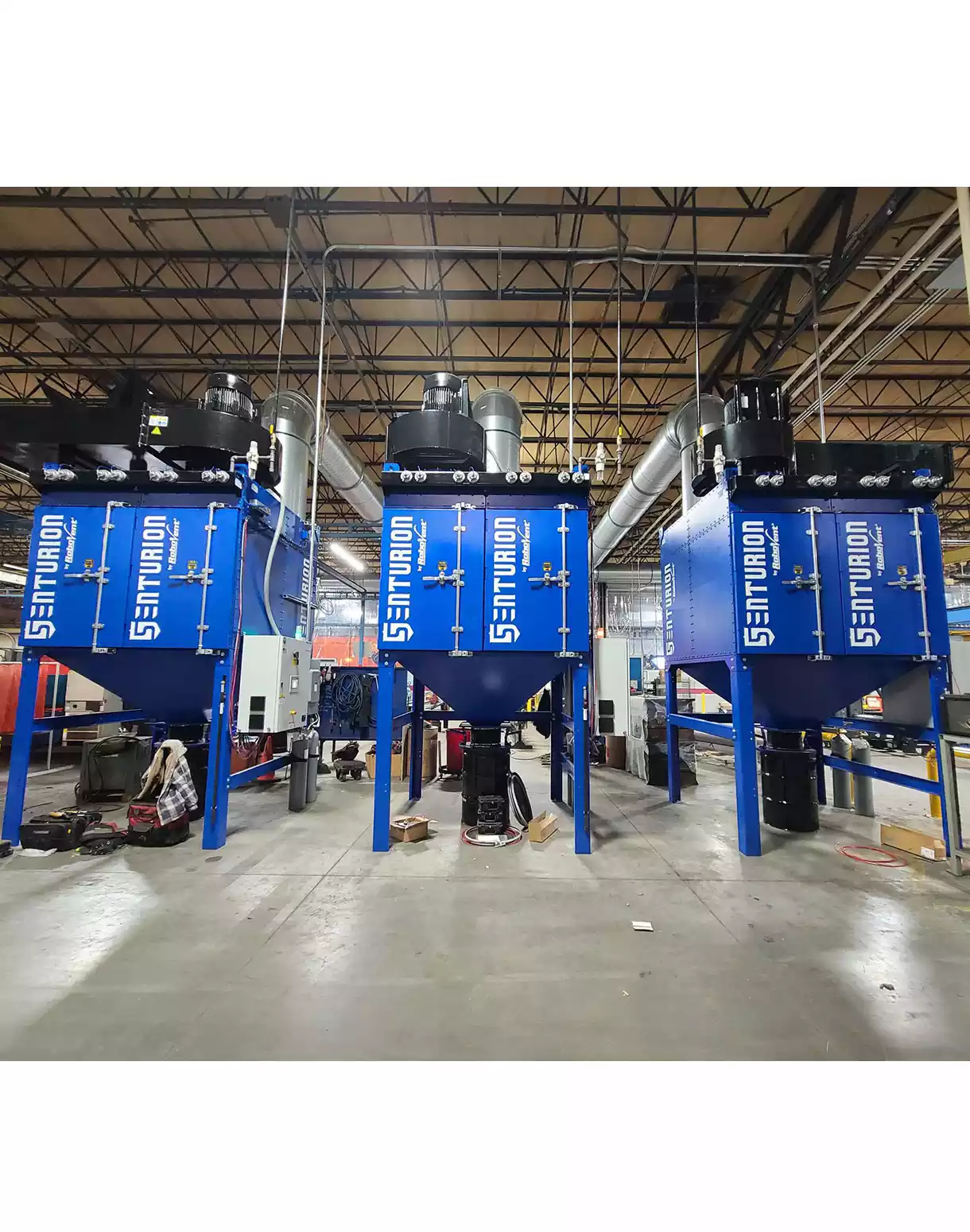

Senturion is the most flexible and versatile industrial dust collector on the market today. Our unique modular system allows us to rapidly design and build a dust collection system tailored to your exact specifications—while saving project costs and timelines. And Senturion is built tough for endurance and high performance in challenging environments.

CUSTOMIZED DUST CONTROL FAST PROJECT TIMELINES.

How do we do it? Senturion is built on a revolutionary modular system with components that fit together like building blocks. This modular design allows us to create a dust collection system that can be adapted for virtually any dust or fume collection application, configured around the physical constraints of your facility. With our advanced filter technology, Senturion has the smallest footprint per CFM available.

- Save floor space.

- Reduce lead time for installation.

- Reduce project costs.

SENTURION FEATURES

READY TO GUARD AND PROTECT

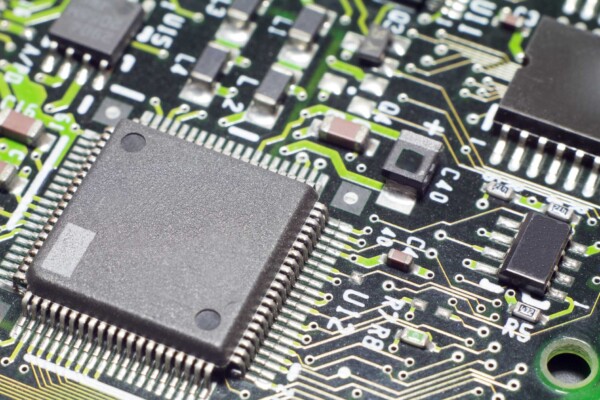

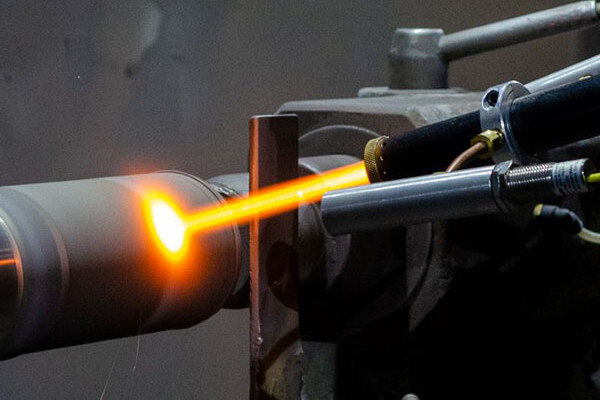

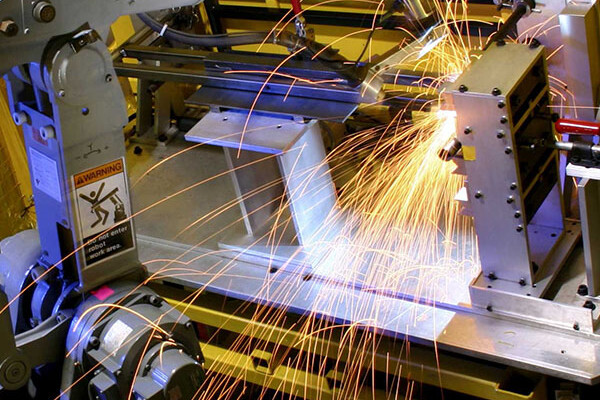

Senturion is ready to guard and protect against any type of particulate, from weld fume and abrasive blasting dust to plastic fines and pharmaceuticals. Get ready to meet the most flexible and versatile dust collector in the industry.

MAXIMUM DUST COLLECTION POWER IN A SMALLER FOOTPRINT

With our advanced filter technology, Senturion has the smallest footprint per CFM available—about 20% smaller than the competition.

THE MOST VERSATILE DUST COLLECTOR IN THE INDUSTRY

With our advanced filter technology, Senturion has the smallest footprint per CFM available—about 20% smaller than the competition.

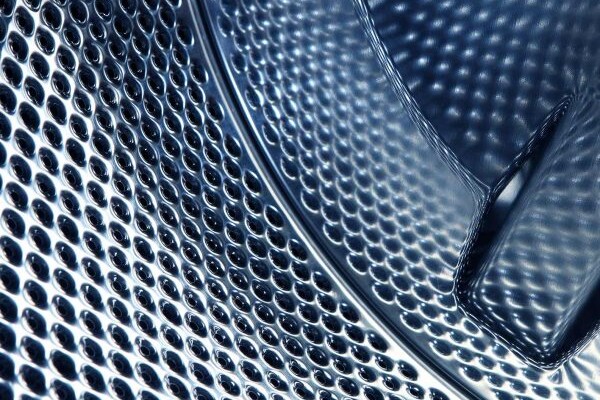

AN INDUSTRIAL DUST COLLECTOR BUILT FOR SAFETY AND ENDURANCE

When we designed Senturion, we rethought everything about industrial dust collector design, from the way the components are manufactured, to the way it is shipped and assembled on site, to the way the unit is maintained.

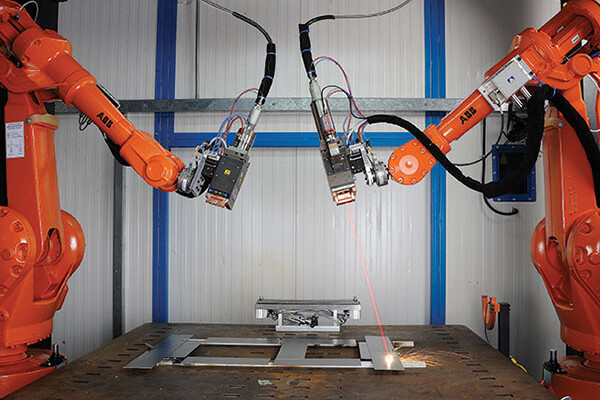

MODULAR SYSTEM BUILT FOR MAXIMUM FLEXIBILITY

The modular system is built from a few simple components for rapid installation, maximum flexibility and space savings. We just configure the cartridge frames to suit your application and then add the right combination of side panels, intakes, hoppers and other optional components.

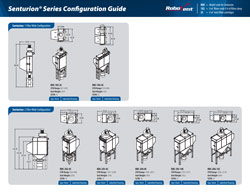

PRODUCT CONFIGURATIONS

The Senturion's modular and versatile construction allows for countless configuration options. Take a look at our Configuration Guide and Configuration Gallery to see some examples.

MEET YOUR CUSTOM SENTURION

Ready to see what your Senturion could look like? Contact RoboVent today to start building your custom dust collection system.