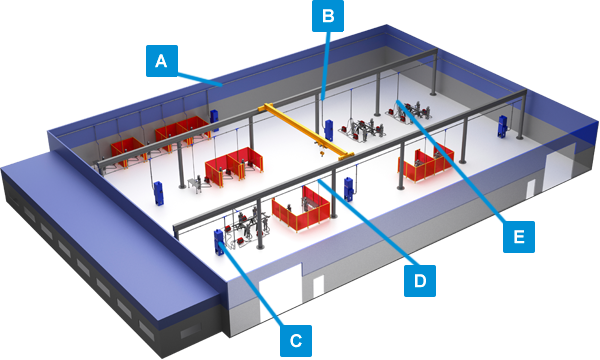

HI-VAC GRID CONFIGURATION

A modular, flexible and future-proof solution

When you want the efficiency and energy savings of a centralized ducted system, but with flexibility to move components if needed, consider RoboVent's Hi-Vac Grid Configuration.

Hi-Vac Grid gives you the flexibility of mobile source capture systems with the efficiency of a centralized ducted hi-vac system. It's a whole-facility solution consisting of modular, standardized ductwork and components that can be easily reconfigured as your needs change.

The Hi-Vac Grid system is:

- Energy efficient: The ducted grid system only needs 70% of the airflow used by individual units, delivering significant energy savings over time.

- Modular: We use standardized, modular components to make installation of your custom system fast and easy.

- Low-maintenance: Our Smart Gate™ Auto Cleaning system directs airflow to clear debris from the system automatically, reducing manual cleaning requirements.

- Flexible: Move components around, expand or reduce capacity, and adjust your system to your new requirements. Modular components and QuickClamp ductwork make it easy to change your configuration as your needs change.

How It Works

- A Primary Grid Duct System The Hi-Vac Grid system is designed using the same principles as a compressed air loop system for optimal efficiency. Component ductwork is configured in a grid across your facility so that welding stations can be added or rearranged easily.

- B Hi-Vac Grid Connectors Modular Hi-Vac Grid Connectors are the same size as the primary Grid ductwork sections, so you can place RoboVent FlexPro hi-vac air filtration units anywhere on the Grid.

- C Standardized One-Size RoboVent Hi-Vac Grid Collector RoboVent produces the most powerful, effective and energy efficient dust collectors on the market. The Hi-Vac Grid system uses standardized hi-vac collectors for maximum flexibility.

- D Grid Process Connectors Grid Process Connectors can be placed anywhere on the primary grid duct system for maximum flexibility. These Process Connectors are used to connect the stations in your process to the primary grid ductwork that is connected to the dust collectors.

- E Delta Gate The DeltaGate is a proprietary connector for welding stations to connect to the RoboVent Hi-Vac Grid system. We combine our proprietary Delta3 spark arrestance technology with a system of automatic gates to control airflow at each cell.

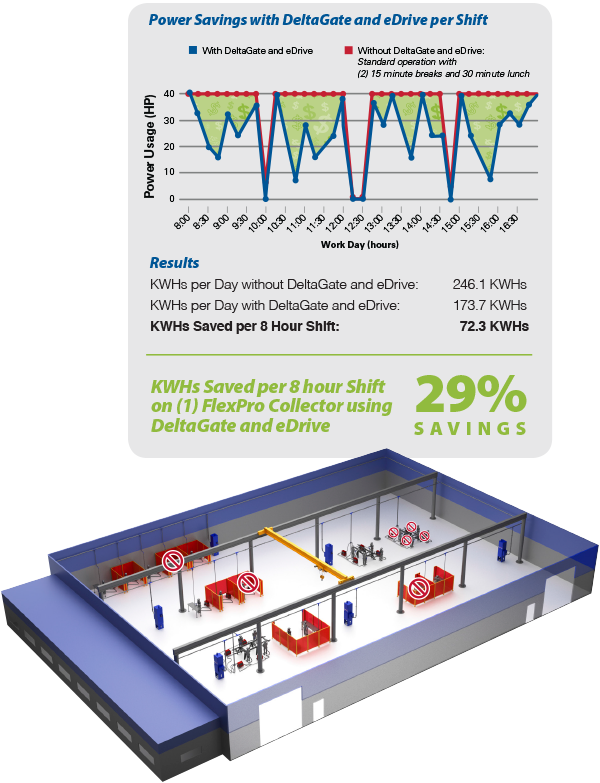

Built for Energy Savings

With the Hi-Vac Grid System, efficiency and energy savings are built right in.

Many facilities simply exhaust dirty air outside, which drives heating bills sky-high during winter months. With the RoboVent Grid system, air is returned to the plant after being cleaned in our highly efficient filtration units. This eliminates a significant loss of energy for manufacturing facilities.

In addition, Grid comes with automated controls that reduce energy consumption automatically. Arc-on time for most robotic welding stations is between 45% and 75%. For manual stations, arc-on time may only be between 20% and 40%. So why pay for the power to run your dust collection system 100% of the time?

With RoboVent’s automated controls, your system is on when you need it, and off when you don’t—delivering significant energy savings.

The DeltaGate system is tied to welding activity. The gates open when the welding arc is on and automatically close a few seconds after the arc turns off. When the gates close, pressure on the system increases and airflow is automatically balanced throughout the system.

The proprietary eDrive Automated VFD comes standard with the Grid System. It works with the DeltaGates to control airflow and adjust the motor speed up or down based on system requirements. That means your system draws power only when it is needed—typically we see an average of a 30% reduction in overall airflow and horsepower required.

RoboVent Hi-Vac Grid Running with 70% of the stations welding: The RoboVent Hi-Vac Grid simulation illustrated on the left shows 7 of 24 stations with their DeltaGates closed. The system includes 6 RoboVent FlexPro collectors. Using the data on RoboVent savings seen in the graph, and assuming an average arc-on time of 71%, the total savings per 8-hour shift would be 434.1 KWHs!

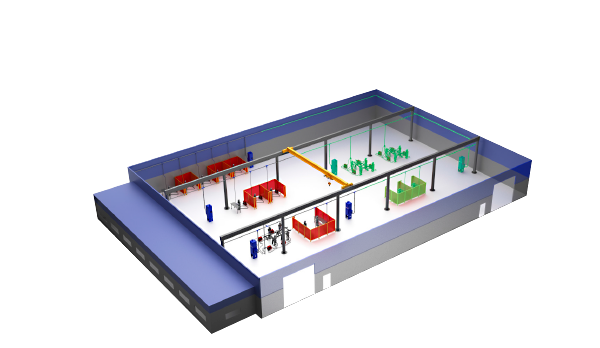

Initial Plant Layout

This image shows a plant with an initial layout and floor plan design with multiple stations and hi-vac collectors. This scenario depicts what your plant layout might look like in normal working and production conditions. As production needs fluctuate and facility-specific manufacturing processes change, the system can be easily altered to accommodate needs.

Production Changes

As your needs change, the system could change right along with you. For example, consider a scenario where you add ten new welding stations, as seen here. In order to accommodate the additional welding fume output, you simply add two additional hi-vac collectors to your configuration.

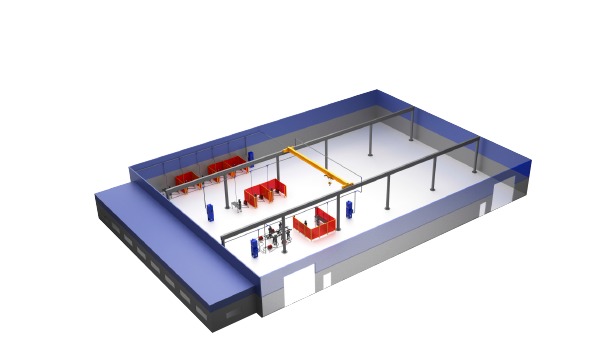

Station Reconfiguration

Now, imagine you have moved two welding stations to the other side of the plant. With the Grid system, the hi-vac collectors can be easily moved to wherever they are needed. The system will automatically self balance to optimize the new configuration.

A plug-and-work smoke-collection system that collects fumes at the source. This powerful air filtration system is perfect for manual and robotic welding applications.

Using groundbreaking technology to kill sparks before they become a problem, the Delta3 protects your workers, your equipment and your productivity.

A welding gun with built-in extraction module to remove weld fumes at the source. The RoboVent Extractor is a lightweight, flexible and powerful tool to protect workers.

QuickClamp Ductwork

A flexible system of ductwork whose components clamp together without tools, RoboVent's QuickClamp Ductwork is flexible, easy to use and reconfigurable.