Complete Guide to Ambient Fume Extraction

Components of an Ambient Air Filtration System

One of the first major choices to be made in choosing a solution for industrial dust and fume control is one between a filtration system and an exhaust system. A filtration system purifies the air, which can be recirculated into a facility, whereas a simple exhaust system just vents the air to the outside. Choosing between ambient air filtration and exhaust ventilation depends on the specific requirements of the workplace, the nature of the contaminants, and the desired level of air quality management.

Air Intake

- The ductless system relies on the air intake plenum, which pulls air into the collector. Since there are no ducts involved, it’s important to carefully plan the placement of the air filtration units within the facility so the air is optimally circulated and captured.

- The air intakes in a ducted system must be positioned within reasonable proximity to the fume/particulate source. This ensures that contaminants enter the ducts rather than drift throughout a facility.

Ductwork

With the ducted air filtration system, the placement of the network of ducts must be carefully planned to maximize airflow efficiency and achieve proper contaminant capture. This includes consideration of every bend and turn in the ducts for reduced air resistance. Most designs feature ducts placed close to the ceiling, where rising emissions are captured and passed through the intake ducts to the dust collector. The ducts are connected to a large dust collector either inside or just outside of the facility where the air is cleaned. The air is then routed back inside, and the clean air is dispersed via the air supply ducts.

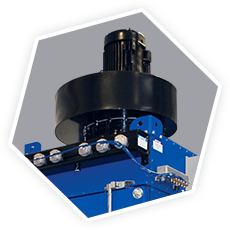

Pulse Jet Cleaning

To prolong the life of the filter, the dust collection system should be equipped with filter pulsing mechanisms. This technology delivers periodic pulses of compressed air across the entire ambient air filter, which dislodges particulates that have become caked onto the media. Online pulsing is used while in operation to prevent particles from embedding into the filter, while offline pulsing is used to remove the particles from the filter and allow them to fall into the containment. The dislodged particulate then falls into a capture compartment where it can be disposed of. This process maintains a clear path for air to flow into the filters and for clean air to be pushed out of the system, but it also prolongs the overall lifespan of the cartridge filter by ensuring that every part of the filter is not subjected to excess filter loading.

Containment Bin

TALK TO AN EXPERT

Want to learn more? Talk to a dust, mist and fume expert today by filling out the fields below.