DUST AND FUME COLLECTION CHALLENGES IN THE RENEWABLES INDUSTRY

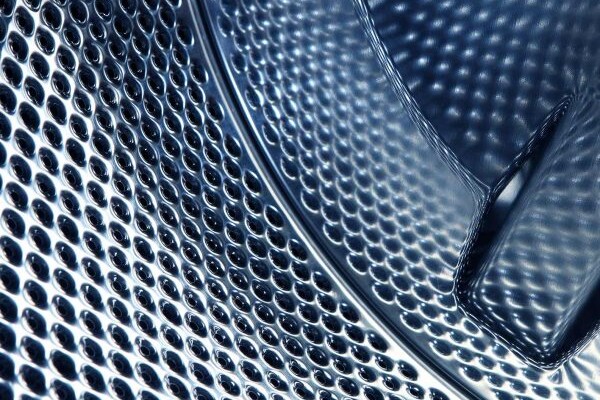

Silica is the basis of most solar panels, and silica dust can be created when silicon wafers are sliced. Regulating this dust is a recent focus of the Occupational Safety and Health Administration (OSHA). In 2016, the agency issued new standards to control this dust in the workplace. Evidence had been growing for years that previous limits on silica dust were not keeping workers safe. OSHA’s new rules are significantly more stringent than previous standards.

While some manufacturers of solar panels will already be in compliance, many will have to take serious measures to address the change. OSHA’s new limit on silica dust cuts the permissible exposure limit (PEL) by half. The new limit is 50 micrograms per cubic meter of air. As with most PEL’s, this limit is measured as an 8-hour time-weighted average. Due to the dangers of silica dust, manufacturers can’t settle for filtering out 80% or so of the dust, as they might with other dusts. With silica, a manufacturer needs to aim for capturing and controlling at least 99.9% of the dust.

The importance of controlling silica dust goes beyond complying with regulations—the dust strongly impacts workers’ health, as well. When inhaled, silica dust can travel deeply into the lungs and cause a number of health problems. The dust is implicated in lung cancer as well as chronic bronchitis and other respiratory diseases. Over time, it can damage other bodily systems, most notably the kidneys. Prolonged exposure can lead to silicosis, a serious disease caused by damage to the lining of the lungs.

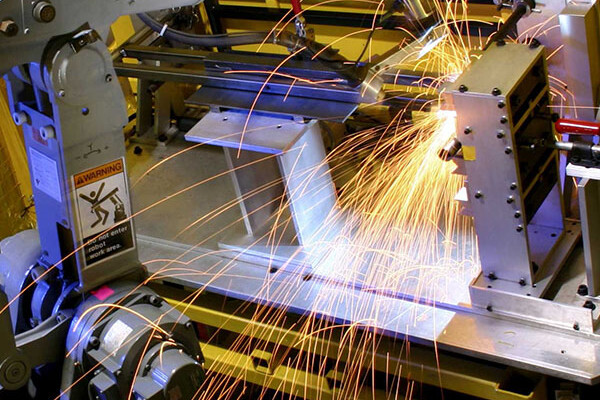

The manufacture of other renewable energy equipment requires a focus on air quality, as well. Building the large metal components for wind turbines, for example, creates serious weld fumes. In particular, the welding of stainless steel—a common practice in this trade—creates weld fumes containing the metallic compound hexavalent chromium. OSHA has a specific regulation for this substance due to its well documented toxicity. Particulates of this substance are extremely small, due to the high temperatures involved in welding. When inhaled, these tiny particulates can travel deep into the body. Hexavalent chromium is a known carcinogen and, when inhaled, has been linked to incidences of cancer. However, this compound is only one of many dangers that travel in weld fumes. Many weld fumes also carry manganese and beryllium, toxic substances that are also regulated by specific OSHA standards.

Whether manufacturers are building wind turbines or large pieces of green infrastructure, the welding of large components presents certain dangers. Because welders must move along a large piece of equipment, source capture of weld fumes is difficult. Conventional capture solutions, such as fume arms and backdraft tables, are difficult or impossible to employ in these situations.

Related Resources

SOLUTIONS FOR DUST AND FUMES IN THE RENEWABLES INDUSTRY

RoboVent understands the renewables industry, and we have an air quality solution for any application. Whether the problem is silica dust, weld fumes, or something else entirely, our comprehensive solutions are thoughtfully designed and based on decades of experience in air filtration. For example, the Fusion Series dust collectors provide power and performance at an unprecedented level of efficiency. These collectors are designed to save energy while delivering the finest filtration possible. This equipment will help you stay green from the ground up.

For a more flexible operation, RoboVent’s line of portable collectors lets you capture dust and fumes at their point of creation. These collectors use fume arms or hoods to make sure welders are protected, as well as everyone in the facility. For a welding operation that has workers moving quickly over large pieces of equipment, a fume gun such as RoboVent’s Extractor is an ergonomic, efficient solution that protects workers and ensures your facility is meeting air quality regulations.

As always, RoboVent guarantees satisfaction. Our manufacturing standards are the highest in the industry, and our warranty is the best in the business.

CONTACT US

Contact one of our industrial dust experts to gain the advantage against dust-generating processes and applications.