WHAT TO LOOK FOR IN DUST COLLECTORS FOR FIBER LASER CUTTING

When switching from CO2 to fiber laser cutting, or when upgrading to a higher wattage laser, it is important to evaluate your current dust collection system and determine whether it is up to the job. Typically, when upgrading to a new laser, the manufacturer will also recommend or require that you purchase a new dust collector. We recommend that you listen to their advice and follow it. In most cases, a more powerful dust collection system will be required.

There are a few considerations to keep in mind when evaluating a dust collector for fiber laser cutting.

- CFM: Dust collectors are rated by CFM (cubic feet per minute). This is the volume of air they are able to move per minute. The higher the CFM of your collector, the more air it will move, and the more filter media you will need.

- Filter media: Make sure you have enough filter media to collect the volume of dust you are producing each minute. The ratio of CFM to filter media (measured in square feet) is known as the air-to-cloth ratio. Applications that produce high volumes of dust, like fiber laser cutting, require more filter media per CFM (or a lower air-to-cloth ratio).

- Pulsing: Dust collector filters are periodically pulsed with short, intense bursts of air to blow off excess dust, which is collected in a bin or tray. This extends the life of the filter media. Without pulsing, the filter rapidly becomes clogged, which prevents the dust collector from doing its job. As we explained above, the tiny, jagged, fast-moving particulates produced by fiber laser cutting are especially prone to becoming deeply embedded in the filter media, making them resistant to pulsing. Keeping your filters clean may require more frequent pulsing or a more aggressive pulsing system that is able to dislodge particulates from the media more effectively.

RoboVent has designed a dust collection system specifically for fiber laser cutting of metals. Senturion is a powerful laser dust collector with a pulsing system that reduces clogging of the filters with fiber dust. Senturion comes in a range of sizes for all kinds of fiber laser cutting applications. An experienced RoboVent air quality engineer can help you evaluate your processes and determine the right size collector for your facility.

Why Manufacturers are Switching to Fiber Laser Cutting

Fiber lasers and CO2 lasers are both used for high-speed cutting, but they have some important differences.

- CO2 lasers produce the laser by running electricity through a tube filled with carbon dioxide gas (often mixed with hydrogen, helium and nitrogen gases). Mirrors at the end of the tube focus the light into a powerful beam capable of cutting through metals, wood, paper, cloth and many other materials.

- Fiber lasers produce the laser beam by channeling light created by a bank of diodes through a fiber optic cable. The fiber cable is similar to the cables used to transfer data in computing and telecommunications. The light is amplified by the fiber optic cable and focused using a lens.

The Dangers of Fiber Laser Cutting Dust

Fiber laser cutting machines produce large volumes of dust when cutting materials at high speed. This dust must be collected and disposed of. Uncontrolled laser cutting dust presents several dangers.

- Damage to laser cutting equipment: When dust is allowed to build up inside the laser enclosure, it can damage expensive laser equipment. Dust can accumulate on sensors, linear actuators and optical lenses, resulting in increased wear and tear, higher chances of a crash, and poorer cut quality.

Controlling High-Volume Fiber Laser Dust

Many manufacturers upgrade their laser cutting equipment without considering the implications for dust collection. This is a mistake. Dust collection systems designed for lower-wattage fiber lasers or CO2 lasers may not be adequate for new high-wattage fiber lasers.

Senturion Sizing & Configuration

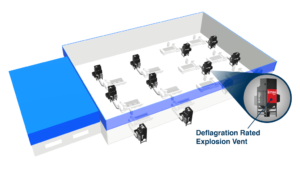

Inside or Outside

Motor blower combinations can be adjusted to suit your application requirements. Senturion can also be modified and built with explosion-proofing for applications that may have combustible dust and need extra safety features with the system.

RECOMMENDED SOLUTIONS

OTHER SOLUTIONS

TOTAL FILTRATION PARTNER

RoboVent is your full turnkey resource for clean air in industrial environments. From facility testing and engineering, to installing equipment, providing replacement filters and preventive maintenance, RoboVent is ready to manage the whole process.

CONTACT US

Contact one of our industrial dust experts to gain the advantage against dust-generating processes and applications.