Examples of Combustible Dust : An Explosive Situation

Preventing Combustible Dust Explosions

Preventing Combustible Dust Explosions

Combustible dust is one of the biggest hazards confronting a wide variety of industries.

- In February 2008, a sugar company in Georgia was leveled by a chain of sugar dust explosions racing through the building. Fourteen workers were killed and 38 others injured. The resulting fines totaled almost 9 million dollars. (Imperial Sugar)

- In December 2010, three persons were killed, and another injured from a metal dust explosion in a blender at a metal recycling plant in West Virginia. (AL Solutions)

- In May 2017, five people were killed and 12 injured from an explosion of grain dust at a grain milling operation in Wisconsin. (Didion Milling)

- In 2018 alone, there were 194 dust fires and explosions in North America, an increase of 25 percent over the year before.

And the one thing they all had in common is they could have been prevented.

What is Combustible Dust?

Combustible dust is a collection of fine, solid particles which, either from a single source or in a mixture with other materials, are liable to catch fire or explode upon ignition when dispersed in the air. Ignition can come from a totally unexpected source. For example, superfine iron dust from a steel shop collected on a filter will spark each time it is hit by a raindrop.

The National Fire Protection Agency (NFPA) defines combustible dust as “any finely divided solid material that is 420 microns or smaller in diameter and presents a fire or explosion hazard when dispersed and ignited in air.” OSHA has created a chart of combustible dust types. If your dust is on that list, then you need to be concerned about combustible dust.

Understanding Kst Values and Volatility

Not all combustible dust is the same. Each type of dust is assigned a Kst value, which provides an indication of the severity of an explosion resulting from the ignition of that dust in a confined space. Some materials, like cornstarch (208 Kst), are identified as extremely hazardous with a high Kst value. They explode quickly, creating a lot of pressure in seconds. Other products, like coffee creamer (28 Kst), burn more slowly, so the pressure rise is slower. But an explosion may still result.

The Kst value—also called the deflagration index, measuring the relative severity of the explosion—is determined by several factors, including the size and chemical nature of your particulates, along with their moisture level. The larger the Kst value, the stronger the possible explosion. A Kst value of 0 will result in no explosion. A value over 0 and below 200 could result in a “weak explosion.” A value between 200 and 300 could result in a “strong explosion.” These substances might include cellulose or flour. A value over 300 could see a “very strong explosion.” These materials might include aluminum or magnesium dust.

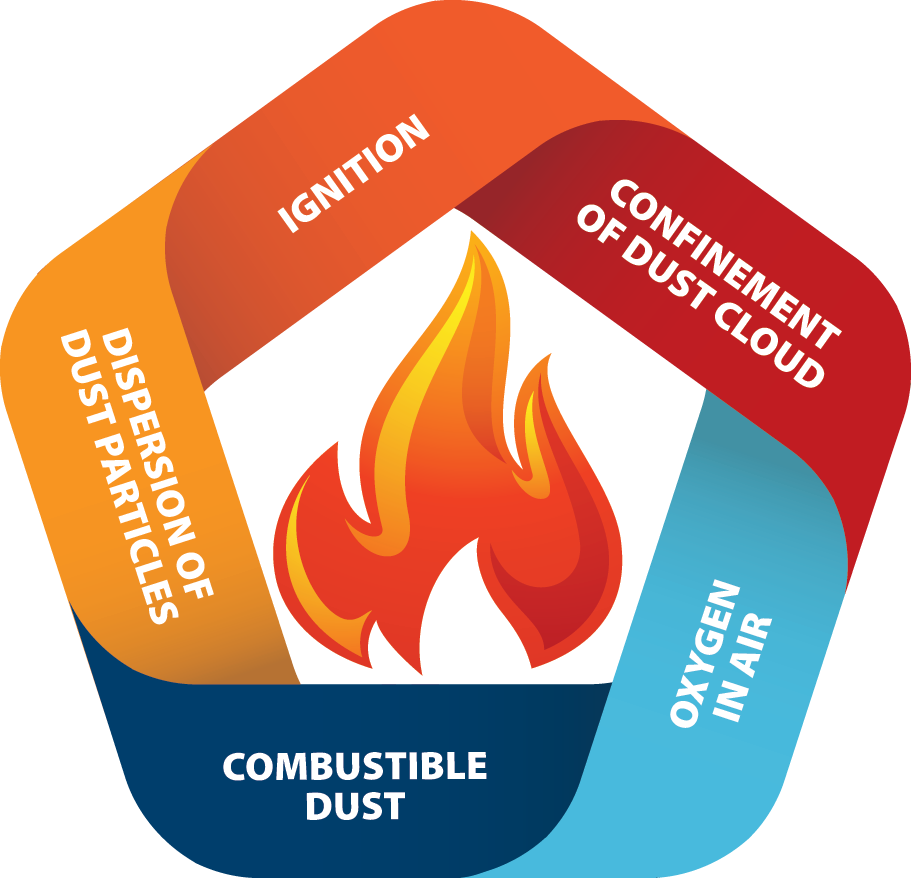

The 5 Elements of a Dust Explosion

There are five required elements for a dust explosion. They are sometimes referred to as the Dust Explosion Pentagon.

- A fuel, which is the combustible dust

- An oxidant, which is typically the oxygen in the air

- An ignition source capable of igniting materials when they are dispersed as a cloud

- Dispersion, which is when the accumulated dust is spread out and creates a dust cloud

- Confinement, which leads to pressure rise and a potential vessel rupture, facility obstruction or structural collapse

Deflagration

A term often used in connection with dust fires and explosions is ‘deflagration,’ which is defined as combustion which propagates through a gas or across the surface of an explosive at subsonic speeds, driven by the transfer of heat. The term is used for both flash fires and explosions. With a dispersed dust cloud, deflagration can cause an unconfined flash fire or, when confined, an explosion that ruptures the containment vessel.

The Two Explosions

Combustible dust explosions often involve two explosions: primary and secondary. The primary explosion is the first to occur when dust suspension in a confined space is ignited and explodes. The first explosion will dislodge other dust that has accumulated, which, when airborne, also ignites. A secondary dust explosion is often more destructive than the primary one.

Combustible Dust Prevention & Mitigation

For all the harm that dust fires and explosions can cause, prevention and mitigation together can all but eliminate the risks to your business.

- Prevention refers to stopping an incident from occurring prior to its incipient stages.

- Mitigation refers to protecting workers, equipment or the environment from an incident after the incipient stages.

Steps for Combustible Dust Explosion Prevention

Explosion prevention begins when one piece of the Dust Explosion Pentagon is removed.

- Remove Combustible Dust: If you can go without storing or creating combustible dust in your facility, you don’t have a dust explosion hazard. For example, perhaps your process could be completed using a material that is not combustible. This approach is safer than any other prevention technique because the fuel is no longer present. However, it is often not possible to eliminate the combustible dust entirely.

- Concentration Reduction: Keeping fuel below the minimum explosive concentration, or MEC, can be done through regular cleaning of your present equipment or selecting new equipment that doesn’t allow dust to accumulate inside it or in the ductwork.

- Oxidizer Reduction: Oxidizer reduction is inerting the atmosphere to bring the oxygen level down below the limiting oxygen concentration, or LOC. This method involves the injection of an inerting gas like nitrogen into a closed system.

- Spark Detection and Control: With this active system, possible ignition sources are detected. Examples include hot screws, smoldering piles, or a hot ember that has been sucked into a dust collection system. These hazards can be detected through the presence of smoke, radiation and high temperatures. They must then activate a control method such as an abort gate that shunts a hot ember out of the processing line or a suppression system that quenches it before it can get downstream and start the incipient stages of a flash fire or explosion.

- Proper Hot Work Systems: Hot work such as welding and cutting should not be done in a dusty environment or on tanks or hoppers containing combustible dust. Clean up the material or empty it from the equipment being worked on before hot work begins.

- Avoid Self-Ignition: Self-ignition can happen in silos where smoldering combustion is deep inside the stored material and turns into flaming combustion when it reaches the surface. This event can ignite a dust or gas explosion in the headspace. Self-ignition can also occur in equipment like spray dryers. Material sticks to the inside edge, heats up and becomes an ignition source for a dust explosion. It is critical to remove this material safely; striking the vessel to dislodge the buildup could ignite an explosion.

- Ignition Source Control: Minimum Ignition Energy, or MIE, is the minimum amount of energy required to initiate the combustion of a cloud of dust, vapor or gas. The lower the number, the more hazardous it is. Making sure the ignition sources in your system or surface temperatures are below the MIE of the dust cloud removes the ignition piece of the Dust Explosion Pentagon and is the final way to prevent an explosion from occurring.

Combustible Dust Explosion Mitigation

Explosion mitigation includes steps to protect workers, equipment or the environment from a combustible dust incident or incident sequence. Mitigation reduces the impact or damage from an explosion after the incipient stages have already begun.

- Containment: Containment refers to increasing the confinement. Explosion-proof pressure vessels on a dust collector can avoid the need for an isolation channel between them. In other cases, such as hammer mills, the equipment is built strong enough to withstand an explosion inside.

- Venting: Venting is a passive approach. The explosion vent is designed to open at a set pressure. When an explosion reaches the set pressure, the vent opens, and the pressure is expelled into the surrounding area.

- Flameless Venting: Flameless venting usually involves a passive explosion vent panel and flame-inhibiting device located within equipment such as a dust collector. As an explosion begins, the explosion vent panel opens, permitting flame and dust to enter the flame-inhibiting device, reducing the flame’s temperature below the dust’s ignition temperature and thereby keeping the flame from spreading and causing an explosion.

- Suppression Systems: Suppression systems actively monitor for the beginning of an explosion. A pressure sensor detects an incident at its incipient stage and activates a control system. This system could suppress the flame or inert the atmosphere so that the flame can’t develop further.

Completing a Dust Hazard Analysis (DHA) for Combustible Dust

Testing is necessary to know both if combustible dust is present in your business and what type of dust it is so that appropriate safety measures can be taken. A Dust Hazard Analysis (DHA) is a systematic review that will identify the potential for a fire, flash fire or explosion hazards associated with combustible particulate solids arising from processes in your facilities.

Components of a DHA

There are five critical elements to a thorough Dust Hazard Analysis:

- Methodology and scope

- Material characterization

- Process characterization

- Hazard analysis and recommendations

- Administrative controls and recommendations

Methodology and Scope

Methodology is important, but there isn’t a specific process that works for every analysis. Frequently it’s a combination of methodologies. One of the most common, and successful, is node-based methodology.

A node can be defined as an environment that has both oxygen and a combustible dust present. A site may have only one such node or it may have nodes reaching into the hundreds. A thorough Dust Hazard Analysis samples each one of these nodes looking for a credible ignition source and a dust concentration level that would support a combustible dust event. This process is greatly assisted when the client has existing Process and Instrumentation Diagrams (P&IDs) or process flow diagrams.

Material Characterization

The second critical element to a DHA is material characterization: listing materials being handled and characterizing them in terms of combustible dust parameters such as maximal pressure (PMax) and rate of pressure rise. The list of materials needs to include manufacturers’ names, where the materials came from and how they’re received.

In the food industry, there are products like flour, sugars and starches whose parameters are well known. In the furniture handling industry, material could be anything from particleboard to a hybrid of wood and plastic. A proper DHA will take samples from the various nodes and decide whether a product needs to be tested further or whether the published data is sufficient to make a risk determination.

Process Characterization

Process characterization involves a variety of steps, including looking at the different nodes, the dust concentration levels that may be present, and the possibility of ignition sources in the different parts of the processes.

It should certainly include a site visit and thorough documentation of every part of the process that is handling combustible dust. The inspector then takes that information and closely examines the credible ignition sources for all those areas.

Hazard Analysis and Recommendations

In the end, the DHA needs to be more than a mere collection of generalized safety concepts. It must contain concrete information that spells out specific threats and identifies either a mitigation or consistent control strategy.

The language needs to be clear and simple. Information should be condensed and put into a format that is readable by everyone from the production manager and workers in the plant to the engineering manager, plant manager, and even the director of the Environmental Health and Safety Group. The report should have as its goal uniting everyone in a team effort to make the facility safer.

Administrative Controls and Recommendations

One aspect of a thorough DHA is an examination of housekeeping practices. In some cases, combustible dust may be building on ledges, building columns, building joists and above false ceilings.

Preventative maintenance recommendations should be a part of the final report. Preventative maintenance could reference filter bag changes on a dust collector or checking bearings on rotating equipment like screw conveyors, bucket elevators, rotary valves and grinding systems. Any one of these can be an ignition source for combustible dust.

Finally, a complete DHA should also take a look at a company’s emergency planning response procedures. If there is an event, how do they handle that? How do they deal with a flash fire? If they have a dust collector that ruptures during an explosion, how do they deal with that?

Combustible Dust Regulations

Both the Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA) have standards for combustible dust that manufacturers must follow.

OSHA Combustible Dust Standards

Combustible dusts are regulated under OSHA’s General Duty Clause (Section 5(a)(1)) with additional requirements under the Hazardous Locations (§1910.307), Hazard Communication (§1910.1200) and Housekeeping (§1910.22) standards. OSHA’s Combustible Dust National Emphasis Program (NEP) outlines policies and procedures for inspecting workplaces that create or handle combustible dusts.

NFPA Combustible Dust Standards

NFPA 654, the Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing and Handling of Combustible Particulate Solids, outlines best practices for preventing dust explosions. Dust collection systems for combustible dusts must also meet NFPA 68, Standard of Explosion Protection by Deflagration Venting, and NFPA 69, Standard on Explosion Preventing Systems. As of September 2020, manufacturers must complete a Dust Hazard Analysis (DHA) of their facility per NFPA Standard 652. This standard provides the basic principles and requirements for identifying and managing the fire and explosion hazards of combustible dusts and particulate solids.

Control Combustible Dust Hazards with RoboVent

We understand combustible dust standards and guidelines and how to meet them, making your facility safer for you and your employees. RoboVent has set the benchmarks in the industrial ventilation industry due to cutting-edge technology and completely integrated solutions. Together, let’s create a Combustible Dust control strategy for your facility.

Contact RoboVent today to learn more about our innovative systems, processes and approach.

REQUEST MORE INFORMATION