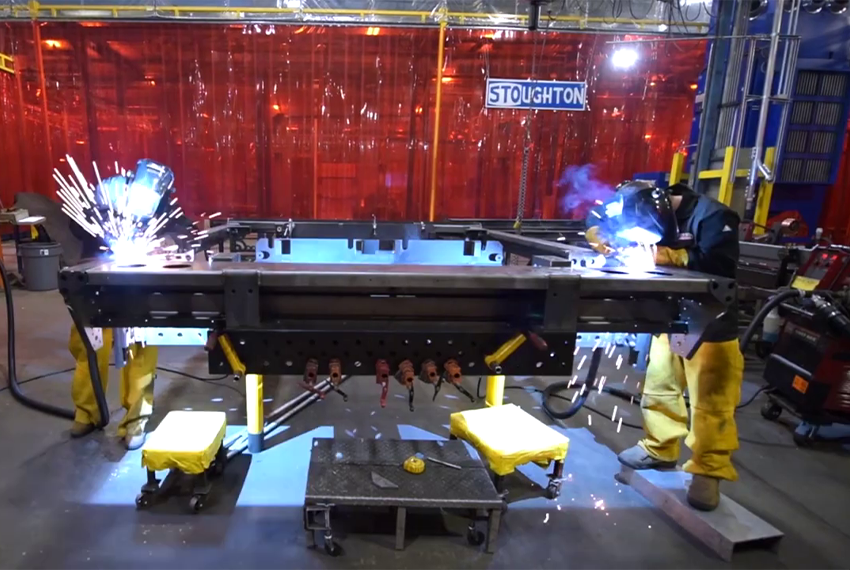

Stoughton Trailers: Creating a Healthier Production Environment

Featured Solution: Ventmapping

Other Solutions: Fume guns, Vortex

Industries: Heavy Equipment

Applications: Manual Welding, Metalworking

Stoughton Trailers recently contracted with air filtration technology company RoboVent, based in Sterling Heights, MI to install a new clean air system in its main manufacturing facility in Stoughton.

RoboVent systems drastically reduce fumes, dust and smoke that welding produces within the manufacturing environment, providing workers with the cleanest air possible.

FEATURED SOLUTION: VENTMAPPING® ENGINEERING

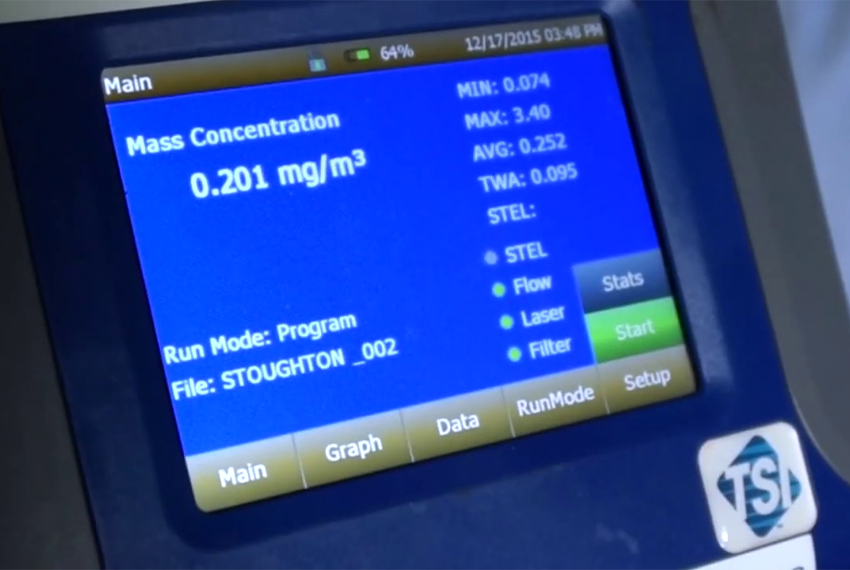

In designing ventilation systems, a key challenge is customizing each system to its unique application and environment. Many factors must be taken into consideration: dust and fume sources, plant layout, existing airflow patterns, future process changes and more. Your motivation and goals matter greatly, as well—these might include any combination of health concerns, plant safety, regulatory compliance and more.